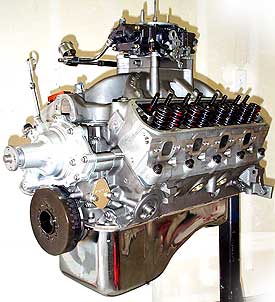

| Engine Assembly,

continued |

56. With the lifters

in place and heads on, we're ready to set the

intake gaskets in place. We're using Fel Pro 1262.

Use a thick RTV bead rather than the cork end

seals. |

57. The Edelbrock Vic. Jr. intake is carefully

set into place, and intake bolts torqued in sequence

to 18 lb. ft. |

58. If done correctly,

the RTV sealant will form a perfect seal between

the intake and block. |

59. Because our

heads have been milled 0.040", the stock

5.0L pushrod length (6.375") was slightly

too long. We ordered a set of Crane 6.250"

hardened pushrods after verifying that length

would yeild optimal roller tip placement. |

60.

Shown here is ideal roller tip positioning on

the valve stem. The roller wheel should be just

slightly towards the intake side of the valve

stem, when the valve is fully closed. At max lift

the roller wheel will be about dead center. The

objective is to select a pushrod length that minimizes

the "sweep", or movement of the roller

tip or wheel across the valve stem. |

61. With the stock

5.0L pushrod length the roller tip was positioned

close tot he outer edge of the valve stem. As

the valve opens the wheel will travel even further

outward, resulting in excessive preloading of

the valve guide. |

62. Most stroker

kits for the 302 utilize a 28oz balance factor.

As we showed in the part 1 of this series, we

had our flywheel balanced to 28oz. At the front

end we ordered up a 28oz hub for our existing

Fluidamper. The 50oz hub is removed and the 28oz

piece bolts right to the outer ring. |

63. One of the

few surprises we encountered with the 331 project

was discovering that the 28oz hub is nearly 1/2"

shorter than the 50oz hub. This is done presumably

to maintain the stock pulley alignment on early

28oz Fords. For us it meant having to order a

custom spacer to work with the single v-groove,

4-bolt pulley we had made specifically for the

50oz hub. |

64. If you look

closely you can make out the timing tape we applied

during the previous 302 buildup. This was necessary

because the timing marks on the FLuidamper, when

clocked with a 50oz hub, are intended to match

up to a late-model timing pointer -the kind that

bolts the timing cover, when the waterpump exits

on the right. Well with the 28oz hub we did not

need the timing tape, the scribes on the damper

ring were dead on with the cast timing pointer

on the early timing cover -why? Again we presume

Fluidamper makes the 28oz hub to work with the

early applications. |

65. Shown is the

Auto Specialties pulley spacer. This will enable

us to line up the crank and waterpump pulleys,

and at $35 it is much cheaper than locating a

set of single groove, four-bolt pulleys (no car

came with such as thing stock as far as we know.) |

|

There you have it, 331

cubic inches cleverly disguised in a 302 body. As

you have read, building a 302 based stroker is not

drastically different from a proper 302 rebuild. There

are some areas which require added consideration during

the assembly process.

In the next article we'll

discuss the final touches to the induction and exhaust

systems supporting the motor. We'll also have the

motor installed in our '67 Mustang and hopefully bring

you some preliminary track and dyno results.

In the mean time look for some articles on what we're

doing to prepare the '67 for it's new powerplant.

F/M

|