|

Copy and Photography by Jim Batie

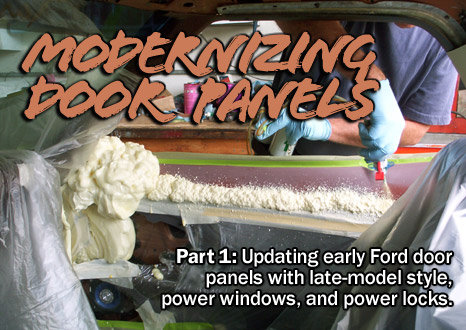

Introduction

Have interior upgrades in traditional magazines left you wondering

how a novice could possibly accomplish such a project? Instead

of making suggestions or simply showing you how one interior

element or another might add a certain look, in this article

FordMuscle is going to perform a "real-world" door

panel upgrade. And yes, when we say "real-world"

we're talking about using junkyard parts.

In a two-part series, we'll demonstrate how we added a modern

appeal to a vintage Ford's door panels. The model of our early

Ford is not critical and if you decide to undertake a similar

project, neither is yours. The critical step is to find a

donor vehicle whose door panels can, with some fabrication,

accommodate the design of your project car's doors. In our

case, we modernized the door panels in a 1972 Ranchero with

door panels from a 1995 Thunderbird. Our specific project

also required the inclusion of power windows and power locks,

an additional challenge FordMuscle was proud to document.

Before Getting Started

We cannot overstate the importance

of planning ahead before embarking on a custom interior upgrade.

Before acquiring the 1995 Thunderbird door panels, we spent

hours measuring and re-measuring our Ranchero's door dimensions

as well as the door panel dimensions of potential donor vehicles.

Over the course of a week or more we

made several trips to the wrecking yard and back to the shop

while planning and looking for complications. Here's what

we did...

This is the original panel on our 1972 Ranchero. The mid-70's

two-door originally came with a standard or a sport door

panel. The sport door panels were already a nice design,

but we wanted something different.

This is the original panel on our 1972 Ranchero. The mid-70's

two-door originally came with a standard or a sport door

panel. The sport door panels were already a nice design,

but we wanted something different. |

|

Initially, these panels from a 1979 Thunderbird appeared

perfect since they included switches for power accessories

and a provision for mounting a driver side remote mirror

control. Unfortunately, they were uncomfortable and not

quite appealing enough for the undertaking.

Initially, these panels from a 1979 Thunderbird appeared

perfect since they included switches for power accessories

and a provision for mounting a driver side remote mirror

control. Unfortunately, they were uncomfortable and not

quite appealing enough for the undertaking. |

| |

|

|

|

This pair of 1995 Thunderbird panels offered a dramatic

update in style that would make the conversion well

worth the effort. These panels offered an armrest that

flows into a smooth door-pull, a nicely molded panel

housing the switches, and a contoured area at the front

for extra knee room. It was obvious that these panels

would require a lot of work to adapt.

This pair of 1995 Thunderbird panels offered a dramatic

update in style that would make the conversion well

worth the effort. These panels offered an armrest that

flows into a smooth door-pull, a nicely molded panel

housing the switches, and a contoured area at the front

for extra knee room. It was obvious that these panels

would require a lot of work to adapt.

|

|

We needed to create a base for the new panel to attach.

We chose a 1/8" thick piece of Luann (that's the

stuff that looks like plywood). Using the OEM door panel

shown in caption one, we simply placed it on the Luann

and marked its outline with a black marker. By cutting

the board with a saber saw we now had a lower section

ready to use. We used the upper section of a standard

Gran Torino door panel (the stamped metal rusty piece)

to accommodate the curve on the top of the door.

We needed to create a base for the new panel to attach.

We chose a 1/8" thick piece of Luann (that's the

stuff that looks like plywood). Using the OEM door panel

shown in caption one, we simply placed it on the Luann

and marked its outline with a black marker. By cutting

the board with a saber saw we now had a lower section

ready to use. We used the upper section of a standard

Gran Torino door panel (the stamped metal rusty piece)

to accommodate the curve on the top of the door. |

| |

|

|

|

Before we could begin trial fitment of the Luann, it

was necessary to remove the manually operated window

regulator and its protruding window crankshaft. Additionally,

we had to remove the stock mechanism for the inside

door release handle.

Before we could begin trial fitment of the Luann, it

was necessary to remove the manually operated window

regulator and its protruding window crankshaft. Additionally,

we had to remove the stock mechanism for the inside

door release handle.

|

|

Now that the inner door was free from obstructions, it

was time to attach the stamped donor sheet metal to the

Luann base. The lower section was clamped to the door

in its proper position. The sheet metal piece was then

installed in its correct position and the two were attached

to each other with several pop rivets.

Now that the inner door was free from obstructions, it

was time to attach the stamped donor sheet metal to the

Luann base. The lower section was clamped to the door

in its proper position. The sheet metal piece was then

installed in its correct position and the two were attached

to each other with several pop rivets. |

Several of the access holes in the inner door frame were

traced to the inside of the Luann board. Once removed,

the access holes were rough-cut and traced to the board

for the other door panel.

Several of the access holes in the inner door frame were

traced to the inside of the Luann board. Once removed,

the access holes were rough-cut and traced to the board

for the other door panel. |

|

In addition to a sabre saw, we used a hole saw and grinder

to resize and enlarge the access holes several times as

the project continued. We eventually eliminated most of

the center of the Luann backing panel.

In addition to a sabre saw, we used a hole saw and grinder

to resize and enlarge the access holes several times as

the project continued. We eventually eliminated most of

the center of the Luann backing panel. |

| |

|

|

Later model Fords use a stepped edge around the outer

perimeter of the door, where the panels mount. As a result,

the donor panels have extra depth to them when compared

to early Ford panels. The excess that was designed to

fit over the step in the Thunderbird door frame was trimmed

to allow the panel to mount flush to the new backing panel.

Later model Fords use a stepped edge around the outer

perimeter of the door, where the panels mount. As a result,

the donor panels have extra depth to them when compared

to early Ford panels. The excess that was designed to

fit over the step in the Thunderbird door frame was trimmed

to allow the panel to mount flush to the new backing panel.

|

|

Here is the excess we removed. Trimming the door panel

was also necessary to provide adequate space between the

seat and the door panel. Small

holes were drilled as a means to mark from the inside

of the door panel flush with the inner surface. These

holes were then connected with a marker and a straight

edge. The material was trimmed off to the high side, allowing

for fitment.

Here is the excess we removed. Trimming the door panel

was also necessary to provide adequate space between the

seat and the door panel. Small

holes were drilled as a means to mark from the inside

of the door panel flush with the inner surface. These

holes were then connected with a marker and a straight

edge. The material was trimmed off to the high side, allowing

for fitment. |

| |

|

|

We were now ready to temporarily

attach the Thunderbird panel to our fabricated backing

panel. This was done using several screws and rivets.

We were now ready to temporarily

attach the Thunderbird panel to our fabricated backing

panel. This was done using several screws and rivets.

We used existing holes and located others where they would

be hidden or covered. |

|

Once properly fitted to the door,

the panels were temporarily attached using two sheet metal

screws. We could now attempt to close the door and see

just how much trimming would be needed to allow the new

panel to fit against the dash. Unfortunately, the door

would barely close half way.

Once properly fitted to the door,

the panels were temporarily attached using two sheet metal

screws. We could now attempt to close the door and see

just how much trimming would be needed to allow the new

panel to fit against the dash. Unfortunately, the door

would barely close half way. |

|