| |

Fabrication(continued)

As shown here, an area of the upper front door panel needed

to be removed to allow the panel to fit next to the dash.

A rough area was marked off and an initial cut to the

panel was made. We were cautious not trim too much material

by making several small cuts. After each cut we gently

tried closing the door. This was an ongoing process until

the door almost completely closed. Finally, the dash was

masked off to prevent any scuffing. With the door held

closed and using the dash as a guide, a more precise cut

line was established on the door panel.

As shown here, an area of the upper front door panel needed

to be removed to allow the panel to fit next to the dash.

A rough area was marked off and an initial cut to the

panel was made. We were cautious not trim too much material

by making several small cuts. After each cut we gently

tried closing the door. This was an ongoing process until

the door almost completely closed. Finally, the dash was

masked off to prevent any scuffing. With the door held

closed and using the dash as a guide, a more precise cut

line was established on the door panel. |

|

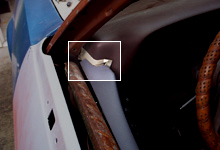

Now that the Thunderbird door

panel was roughly fitted to the Ranchero door, we were

ready to integrate the Thunderbird inside door release

handles. A template was made by taping a sheet of paper

to the Thunderbird door (at the junkyard), covering

the cutout that the door handle slid into. The opening

outline was transferred to the paper and a small hole

was punched through at the point where a mounting screw

hole for the door pull had been marked. Using this hole

as a reference, the template was taped to the project

door, shown above. A simple pass over the paper with

paint from an aerosol can marked the location.

Now that the Thunderbird door

panel was roughly fitted to the Ranchero door, we were

ready to integrate the Thunderbird inside door release

handles. A template was made by taping a sheet of paper

to the Thunderbird door (at the junkyard), covering

the cutout that the door handle slid into. The opening

outline was transferred to the paper and a small hole

was punched through at the point where a mounting screw

hole for the door pull had been marked. Using this hole

as a reference, the template was taped to the project

door, shown above. A simple pass over the paper with

paint from an aerosol can marked the location.

|

| |

|

|

With the location of the new inside

door release handle clearly marked on the project door,

all that was required was to remove the sheetmetal. A

hole saw was used to establish a hole and tin snips were

used to finish cutting the opening along the edge of the

blackened area. A flat file was then used to dress the

edges.

With the location of the new inside

door release handle clearly marked on the project door,

all that was required was to remove the sheetmetal. A

hole saw was used to establish a hole and tin snips were

used to finish cutting the opening along the edge of the

blackened area. A flat file was then used to dress the

edges.

|

|

With the inside releases now installed

on the doors, the panels are reinstalled to check for

proper location. The Thunderbird handles slide into the

opening and once slight adjustments were made front to

rear, two screws were used to lock them in place. Neither

the old nor the newer pull rods used to connect the inside

handle to the latch fit perfectly. The original rods gave

the best overall alignment.

With the inside releases now installed

on the doors, the panels are reinstalled to check for

proper location. The Thunderbird handles slide into the

opening and once slight adjustments were made front to

rear, two screws were used to lock them in place. Neither

the old nor the newer pull rods used to connect the inside

handle to the latch fit perfectly. The original rods gave

the best overall alignment. |

| |

|

|

An increase in length of approximately

1/2" was needed on the door-release pull rod. Using

a straight edge, a line was marked along the rod at one

end and two cross marks were made at a predetermined distance

apart. The rod was then cut in two. A small piece of tubing

was then slid over the rod pieces. Using the alignment

mark and adding 1/2" to the distance between the

cross marks the unit was tack welded together. A quick

test fit and the doors could be opened from the inside.

When removed, the rods were braised all around a both

ends. Next, we began the

installation of the power door locks.

An increase in length of approximately

1/2" was needed on the door-release pull rod. Using

a straight edge, a line was marked along the rod at one

end and two cross marks were made at a predetermined distance

apart. The rod was then cut in two. A small piece of tubing

was then slid over the rod pieces. Using the alignment

mark and adding 1/2" to the distance between the

cross marks the unit was tack welded together. A quick

test fit and the doors could be opened from the inside.

When removed, the rods were braised all around a both

ends. Next, we began the

installation of the power door locks. |

|

We've noticed that for many years

the door latch mechanisms used in Ford products are set

up to accommodate power door locks whether they are installed

or not. The latches on our project car were no different

and only a hole at the back of the door, for mounting

purposes, was needed to install the power units from the

1995 Thunderbird. The location for these holes was very

difficult to mark on the inside of the door. A bit of

luck and guesswork was used in determining the hole location.

Once marked and center punched, a small hole was dilled

from the inside out. The hole was then enlarged by drilling

from the outside in. The push-pull rod was attached to

the door latch and the power lock attached to the door.

A power source and a pair of jumper wires were used to

check for proper operation.

We've noticed that for many years

the door latch mechanisms used in Ford products are set

up to accommodate power door locks whether they are installed

or not. The latches on our project car were no different

and only a hole at the back of the door, for mounting

purposes, was needed to install the power units from the

1995 Thunderbird. The location for these holes was very

difficult to mark on the inside of the door. A bit of

luck and guesswork was used in determining the hole location.

Once marked and center punched, a small hole was dilled

from the inside out. The hole was then enlarged by drilling

from the outside in. The push-pull rod was attached to

the door latch and the power lock attached to the door.

A power source and a pair of jumper wires were used to

check for proper operation. |

Wiring Harnesses and Schematics

Now that the door releases

and power lock mechanisms were installed, it was time to move

to the second stage of the upgrade. This phase will focus

on the adaptation of the door wiring harness from the Thunderbird

to the project vehicle. Many hobbyists dread working with

the electrical systems of their car. Working with a wiring

harness is, in our opinion, one of the easiest components

in the electrical system to create or repair.

The key to working with a wiring harness

is to have a clear objective. Understanding color codes and

what components the color codes correspond to is mandatory

and simple if you have a wiring schematic. We suggest making

enlarged copies of the appropriate schematic and identifying

what wires and components you will be working on. If you have

a basic plan you will succeed. After all, it's as simple as

connecting point A to point B.

Wiring for Door Locks and Power Windows

To begin the wiring phase of our door panel upgrade, we needed

to identify all the required wires in the Thunderbird harness.

Unnecessary wires were to be elimated. The first step was

to mark wires needed for the door locks, power windows, power

mirrors, etc. with masking tape and a marker. The panel light

at the rear of the door uses a separate, two-wire harness,

and it was set aside. There would be no need for the wires

used by the Thunderbird keyless entry and door ajar warning

system. After removing most of the tape on the wiring harness,

the wires needed for the keyless entry and door ajar system

were eliminated. The wires and connector for the power mirrors

were identified and set aside for future use.

The factory door panel harness

was removed from the Thunderbird. We removed the tape

for access to the wire bundles. Care was taken not to

cut or remove any insulation from any of the wires.

The factory door panel harness

was removed from the Thunderbird. We removed the tape

for access to the wire bundles. Care was taken not to

cut or remove any insulation from any of the wires. |

|

By referring to a 1995 Thunderbird

schematic, we marked all the wires needed for the door

locks, power windows, power mirrors, etc. with masking

tape and a marker. The panel light at the rear of the

door uses a separate two-wire harness, which we did not

need.

By referring to a 1995 Thunderbird

schematic, we marked all the wires needed for the door

locks, power windows, power mirrors, etc. with masking

tape and a marker. The panel light at the rear of the

door uses a separate two-wire harness, which we did not

need. |

| |

|

|

Next, we removed all the wires

for the keyless entry, door ajar warning system, and power

mirrors. That left us with a nice pile of wires that we

did not have to deal with. Now we started the process

of installing the harness into the project door.

Next, we removed all the wires

for the keyless entry, door ajar warning system, and power

mirrors. That left us with a nice pile of wires that we

did not have to deal with. Now we started the process

of installing the harness into the project door. |

|

We started the temporary installation

of the harness by connecting it to the switches in the

door panel and then installing the door panel onto the

vehicle. This provided a starting point for the harness

placement.

We started the temporary installation

of the harness by connecting it to the switches in the

door panel and then installing the door panel onto the

vehicle. This provided a starting point for the harness

placement. |

| |

|

|

|

All corrections or additions

were done as we worked away from the factory connectors

at the switch panel. The wires were massaged to lie

in their new positions with the main bundle going forward

and the other going toward the rear of the door. The

main forward bundle would eventually find its way through

the stock bellow.

All corrections or additions

were done as we worked away from the factory connectors

at the switch panel. The wires were massaged to lie

in their new positions with the main bundle going forward

and the other going toward the rear of the door. The

main forward bundle would eventually find its way through

the stock bellow.

|

|

A metal bracket was used to attach

the main harness at the front of the door, keeping the

harness away from the moving glass on the inside of the

door. A second insulated, loop-type clamp was used to

locate the harness to the outer side of the doo, this

was simply attached to a protruding hinge-bolt.

A metal bracket was used to attach

the main harness at the front of the door, keeping the

harness away from the moving glass on the inside of the

door. A second insulated, loop-type clamp was used to

locate the harness to the outer side of the doo, this

was simply attached to a protruding hinge-bolt. |

| |

|

|

It was obvious that the wires for

the power window motors and the power door locks were

well short of the required length. An additional hole

was needed to allow the power window connector to be on

the outside of the door yet behind the panel. Masking

tape and wire ties were used to locate the wires in approximate

locations.

It was obvious that the wires for

the power window motors and the power door locks were

well short of the required length. An additional hole

was needed to allow the power window connector to be on

the outside of the door yet behind the panel. Masking

tape and wire ties were used to locate the wires in approximate

locations. |

|

Using wire of the same gauge and

color, we fitted the wire in-line between the factory

connectors to add additional length. The work done to

this point was all performed on the driver's door and

harness. You can easily see the additional length added

to the yellow, white, and pink wires.

Using wire of the same gauge and

color, we fitted the wire in-line between the factory

connectors to add additional length. The work done to

this point was all performed on the driver's door and

harness. You can easily see the additional length added

to the yellow, white, and pink wires. |

| |

|

|

On the bench and using the left

driver's side harness as a pattern, we duplicated the

harness for the passenger side.

On the bench and using the left

driver's side harness as a pattern, we duplicated the

harness for the passenger side. |

|

Once both harnesses were roughed

out, the wire bundles were laid out neatly. Wrapping the

wires tightly with electrical tape at random points made

wrapping the entire harness much easier. We added wires

for the door mounted speakers.

Once both harnesses were roughed

out, the wire bundles were laid out neatly. Wrapping the

wires tightly with electrical tape at random points made

wrapping the entire harness much easier. We added wires

for the door mounted speakers. |

| |

|

|

We wrapped the entire harness.

The "dry vinyl wrap" shown is from Eastwood.

Since the final length of the harness going through the

cowl was not yet determined, an additional length was

wrapped as a precautionary measure. It's easier to remove

the harness tape and shorten the harness than to be forced

into extending it.

We wrapped the entire harness.

The "dry vinyl wrap" shown is from Eastwood.

Since the final length of the harness going through the

cowl was not yet determined, an additional length was

wrapped as a precautionary measure. It's easier to remove

the harness tape and shorten the harness than to be forced

into extending it. |

|

Now that the wire harness was finished

it was reinstalled one final time. Proper fit was checked

and the snap-in-clips for locating sub-sections of the

harness to the door were installed. These are the same

clips that were removed from the original harness used

in the Thunderbird. The clips were installed at various

points using existing holes and fastened to the harness

using friction tape just as they were by the manufacturer.

Now that the wire harness was finished

it was reinstalled one final time. Proper fit was checked

and the snap-in-clips for locating sub-sections of the

harness to the door were installed. These are the same

clips that were removed from the original harness used

in the Thunderbird. The clips were installed at various

points using existing holes and fastened to the harness

using friction tape just as they were by the manufacturer.

|

What's Coming Next?

In part two of this upgrade the Thunderbird door panels

will be permanently attached to the mounting panels and then

molded together as a unit. The doors will be prepped as needed

and readied for paint. In an effort to provide mounting integrity,

several pieces of sheet metal will be welded on to the door

to provide a place for fasteners. Here is a preview.

|