With the main cap bolt holes clear of machining debris,

we installed ARP studs just a pinch more than finger tight.

With the main cap bolt holes clear of machining debris,

we installed ARP studs just a pinch more than finger tight. |

|

The main saddles were wiped clean with brake cleaner and

lint-free towels.

The main saddles were wiped clean with brake cleaner and

lint-free towels. |

| |

|

|

Here we are installing the "block-side" Clevite

77 main bearings. The "block-side" main bearing

halves incorporate an oiling groove. The grooved thrust

bearing goes on journal number three.

Here we are installing the "block-side" Clevite

77 main bearings. The "block-side" main bearing

halves incorporate an oiling groove. The grooved thrust

bearing goes on journal number three. |

|

We used lithium based Comp

Cams Engine Assembly Lube to coat the main bearings

once they were installed.

We used lithium based Comp

Cams Engine Assembly Lube to coat the main bearings

once they were installed. |

| |

|

|

Once wiped down, the crank was ready ride the saddles.

Once wiped down, the crank was ready ride the saddles. |

|

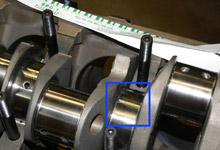

The crank was carefully set in place with caution to avoid

bumping a journal on a main stud.

The crank was carefully set in place with caution to avoid

bumping a journal on a main stud. |

| |

|

|

After wiping down the main caps, we set the other half

of the main bearings into place. No oil or assembly lube

required here.

After wiping down the main caps, we set the other half

of the main bearings into place. No oil or assembly lube

required here. |

|

Now was the right time to check main bearing clearance,

therefore no assembly lube was applied to the crank side

of the bearing surfaces yet.

Now was the right time to check main bearing clearance,

therefore no assembly lube was applied to the crank side

of the bearing surfaces yet. |

| |

|

|

We used "Green" Plastigauge and set a length

across one of the main journals. "Green" Plastigauge

is for measurements between 0.001" and 0.003"

inch - typical engine bearing clearances.

We used "Green" Plastigauge and set a length

across one of the main journals. "Green" Plastigauge

is for measurements between 0.001" and 0.003"

inch - typical engine bearing clearances. |

|

We proceeded to install all five main caps. The thrust

main bearing and cap goes on journal number three.

We proceeded to install all five main caps. The thrust

main bearing and cap goes on journal number three. |

| |

|

|

ARP hardware requires the use of the included ARP moly.

We applied some to the threads of each stud.

ARP hardware requires the use of the included ARP moly.

We applied some to the threads of each stud. |

|

The caps were installed in an alternating sequence to

90 ft lbs. Once torqued down, the main caps were ready

for removal.

The caps were installed in an alternating sequence to

90 ft lbs. Once torqued down, the main caps were ready

for removal. |

| |

|

|

Don't use a torque wrench to remove anything. Here, we're

using a long breaker bar to break the nuts free of the

main studs.

Don't use a torque wrench to remove anything. Here, we're

using a long breaker bar to break the nuts free of the

main studs. |

|

Some light upward tapping with a hammer helps dislodge

the main caps.

Some light upward tapping with a hammer helps dislodge

the main caps. |

| |

|

|

We carefully lift the main cap to expose the journal where

the Plastigauge was applied.

We carefully lift the main cap to expose the journal where

the Plastigauge was applied. |

|

The Plastigauge indicated a main bearing to crankshaft

clearance of between .0015" and .002". The allowable

range for the Ford 400 is .0009" and .0026".

Success!

The Plastigauge indicated a main bearing to crankshaft

clearance of between .0015" and .002". The allowable

range for the Ford 400 is .0009" and .0026".

Success! |

| |

|

|

With the main bearing clearance confirmed as allowable,

we wiped the main bearings and caps clean, reinstalled

them and applied some assembly lube the "crank-side"

surfaces.

With the main bearing clearance confirmed as allowable,

we wiped the main bearings and caps clean, reinstalled

them and applied some assembly lube the "crank-side"

surfaces. |

|

The main caps were then reinstalled and torqued once again.

To reemphasize, this was not our final installation of

the crankshaft for this build.

The main caps were then reinstalled and torqued once again.

To reemphasize, this was not our final installation of

the crankshaft for this build. |