|

Port Mold Analysis

Before reviewing any flow and swirl

data on our Cleveland heads, we took port

molds of the intake and exhaust runners on all three heads

(2V, 4V, and Edelbrock). You may have see FordMuscle perform

this process in other articles. Once cured and removed, the

silicone molds are great supportive visuals for the corresponding

flow data found on Page

4 of this article. Here's the process in case you ever

want to try this at home. It's a good technique if you plan

on home porting any cylinder head.

We popped an intake and exhaust valve from each head.

We popped an intake and exhaust valve from each head.

|

|

Mixed up the silicone RTV and catalyst.

Mixed up the silicone RTV and catalyst. |

| |

|

|

Waited 6 hours for the exhaust port molds to cure.

Waited 6 hours for the exhaust port molds to cure.

|

|

Carefully coaxed them out of each head then repeated the

process for

Carefully coaxed them out of each head then repeated the

process for

the intake side. |

Intake

Runners Intake

Runners

Intake runner design, shape, and

contour is almost completely responsible for a cylinder head's

intake flow velocity and ability to promote, prevent, or control

the mixture's motion or swirl effect. The following visual

comparison of our Cleveland intake runner molds offers information

not seen by simply looking at an intake port's footprint or

peering into the dark corridor we call the intake runner.

Pictured from left to right is the factory 351C 4V intake

runner, the factory 351C 2V intake runner, and Edelbrock's

Performer RPM 351C intake runner. The average joe may not

notice the subtleties between these three blue globs, but

hardcore enthusiasts, cylinder head porters, and design engineers

can quickly point to the improvements of modern head design

over early 1970's designs. Let's take a closer look:

|

Factory

Iron 351 Cleveland 2V Head Intake Port

|

Profile View

The factory 2V intake runner shows a hard turn towards

the valve forming an undesirable and abrupt "L"

shape. Also, note the bullnose that essentially forces

the intake charge into the runner wall right above the

valve.

|

|

Top View

From the top, the 2V intake runner has a fairly consistent

cross-section

which by itself is conducive to maintaining the velocity.

However, based on the previous photo and the obtrusive

valve guide boss (shown as an impression around the valve

stem here) this runner can be improved with porting and

machine work.

|

| |

|

|

|

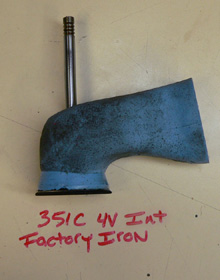

Factory

Iron 351 Cleveland 4V Head Intake Port

|

Profile View

The profile of the notorious 4V intake runner is like

a bloated version

of the 2V runner. The mold shows the same bullnosed "L"

shape, unlike the 2V however, the 4V's port entry has

a distinct "hogged-out" floor which creates

an unwanted high static pressure area. This area is sometimes

filled-in with epoxy or special port plates to give the

intake charge a straighter shot at the valve, these modifications

will help maintain flow velocity. (See sidebar)

|

|

Top View

From the top, the 4V runner contradicts modern aftermarket

runner designs with a "quick pinch" followed

by a large jog outward as the runner approaches the valve.

In theory, the sudden change in cross-section from small

to large can only serve to slow flow velocity. While the

"quick pinch" may act in a venturi effect to

increase velocity, the effect is happening too soon slowing

the charge well before the intake valve. However, the

shear size of the port alone is what always contributes

to high flow numbers for the factory 4V head. As with

the 2V head, the obtrusive valve guide boss is also apparent. |

| |

|

|

|

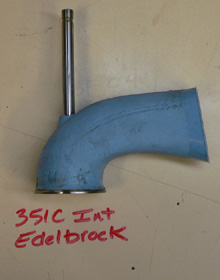

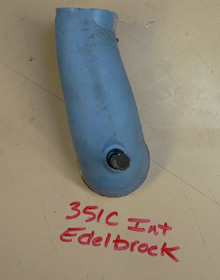

Edelbrock

351 Cleveland Head Intake Port

|

Profile View

The profile of the Edelbrock intake runner is a clear

testament to modern computer-aided cylinder head design.

Note the contoured shape that forms a "J" rather

than an "L" like the factory iron head. There

are no sharp turns or obstructions. The cross- section

is a bit larger than the factory 2V but much smaller than

the 4V. The cross-section gradually decreases in size

as the charge approaches the valve, this helps increase

flow velocity. Gone is the bullnosed shape that sends

the mixture crashing into the runner wall. |

|

Top View

There's nothing too exciting about the Edelbrock intake

runner when viewed from above, and that's a good thing!

The lack of character indicates an unobstructed straight

shot at the intake valve. As with most modern cylinder

head designs, the valve guide boss does not protrude into

the runner. Designs like these, by their nature, can create

a controlled swirl effect. We'll discuss swirl on Page

3 of this article. |

Exhaust Runners

Like intake runners, an exhaust runner's design, shape, and

contour influence flow potential. While you may have been

running Cleveland heads all your life, you probably have not

seen the exhaust ports of a 2V and 4V displayed as we've done

here. Let's take a look.

(The

Twist on Swirl, Flow and Swirl Testing) (The

Twist on Swirl, Flow and Swirl Testing)

|