|

The Twist on

Swirl

Since

the Cleveland flow data we gathered for this article included

thought-provoking swirl data and because "swirl"

is a term you'll see tossed around internet forums and magazine

pages, we thought we'd research the mysterious "twist".

In doing so, FordMuscle opened the proverbial "can-of-worms"

in trying to define the advantages and disadvantages of swirl

by consulting various industry professionals like Rick Roberts

from Edelbrock, Tony Mamo from Air Flow Research, Joe Sherman

of Joe Sherman Racing Engines, and John Yelich from CHW. We

also scoured our own reference materials and even referred

to a UC Irvine study on the subject from their Department

of Mechanical and Aerospace Engineering (see second sidebar

below). Here's what we found. Since

the Cleveland flow data we gathered for this article included

thought-provoking swirl data and because "swirl"

is a term you'll see tossed around internet forums and magazine

pages, we thought we'd research the mysterious "twist".

In doing so, FordMuscle opened the proverbial "can-of-worms"

in trying to define the advantages and disadvantages of swirl

by consulting various industry professionals like Rick Roberts

from Edelbrock, Tony Mamo from Air Flow Research, Joe Sherman

of Joe Sherman Racing Engines, and John Yelich from CHW. We

also scoured our own reference materials and even referred

to a UC Irvine study on the subject from their Department

of Mechanical and Aerospace Engineering (see second sidebar

below). Here's what we found.

By definition, swirl is the term for the corkscrew movement

of an air-fuel mixture down the last few inches of the intake

runner and into the cylinder, similar to the vortex you see

when the last few gallons of water drain out of your bath

tub. For those cylinder heads that do exhibit a swirl effect,

the point at which a swirl is initiated based on valve lift

can show great variation as you'll see with our subject Cleveland

heads.

The

illustration above showing an air-fuel path around the intake

valve and into the combustion chamber is really the best way

to visualize the phenomenon of swirl. Albeit, this image is

greatly simplified for the purpose of gaining a quick understanding.

The movement seems clear, looks powerful, and at first glance

you might be inclined to say... Why that's gotta be the optimum

intake charge for any head!

Unfortunately, for the enthusiast, there are a few lines of

thought in the professional realm as it relates to swirl and

whether it should be chased after, chased away, or politely

ignored. These attitudes prevail within original cylinder

head design as well as with engine builders and head porters.

With that aside, the common opinion among professionals is

that swirl is an important factor in atomization and combustion

efficiency, although research on swirl specifically (as opposed

to broader subject of turbulent flow) has not

provided a foundation for which to draw any hard and fast

conclusions.

Unfortunately, for the enthusiast, there are a few lines of

thought in the professional realm as it relates to swirl and

whether it should be chased after, chased away, or politely

ignored. These attitudes prevail within original cylinder

head design as well as with engine builders and head porters.

With that aside, the common opinion among professionals is

that swirl is an important factor in atomization and combustion

efficiency, although research on swirl specifically (as opposed

to broader subject of turbulent flow) has not

provided a foundation for which to draw any hard and fast

conclusions.

Regardless, we've simplified two

common positions on swirl that you might come across. Let

us warn you that after reading the positions you'll still

be forced to draw your own conclusions regarding what remains

a quiet controversy. And while our three Cleveland head's

flow data show interesting variations in swirl behavior, the

only real test would be to throw each head on one motor designed

for a specific application and dyno test the different combos.

Common Argument for Promoting Swirl

Common Argument for Promoting Swirl

Swirl increases the mixing of fuel and air by diffusing the

mixture to the

swirl path's centerline by forming a recirculation zone. Swirl

increases

combustion efficiency through increased atomization. (See

sidebar "UC Irvine Mechanical and Aerospace Engineering

Studies Combustion Enhancement Using Induced Swirl").

Common Argument for Eliminating Swirl

Common Argument for Eliminating Swirl

Swirl decreases the mixing of fuel and air by "flinging"

fuel particles

out of suspension in a centrifugal effect. Too create swirl

an intake

runner must be shaped to promote the effect. Swirl promoting

"shapes" in the form of unique intake contours or

turns will impede an intake charge's rate of flow.

Keep

the two positions above in mind next time you see the term

"swirl" used by a peer, a manufacturer, or even

included on your own cylinder head's flow chart. According

to Rick Roberts, Edelbrock's Director of Engineering, a more

accurate way of rating the performance of an intake or exhaust

runner is to measure the head's flow coefficiency. Flow Coefficient

or the relationship between the pressure drop across an orifice

and the corresponding flow rate (Static Pressure and Velocity)

provides us with measurable, dependable, and relevant scientific

results. Swirl is just one aspect that can affect the Flow

Coefficient.. Keep

the two positions above in mind next time you see the term

"swirl" used by a peer, a manufacturer, or even

included on your own cylinder head's flow chart. According

to Rick Roberts, Edelbrock's Director of Engineering, a more

accurate way of rating the performance of an intake or exhaust

runner is to measure the head's flow coefficiency. Flow Coefficient

or the relationship between the pressure drop across an orifice

and the corresponding flow rate (Static Pressure and Velocity)

provides us with measurable, dependable, and relevant scientific

results. Swirl is just one aspect that can affect the Flow

Coefficient..

Just show

me the Cleveland flow numbers please!

| |

|

Turbulent Flow and Swirl

The term "swirl" fits into the broader and more

comprehensive category of turbulent flow. To express the

swirling action of the pesticide stream coming off the

tip of this crop duster in RPMs alone may be a bit short-sighted. |

| |

A Look Beyond Swirl

While a swirl meter integrated

into a flowbench can provide a reference point by which to

rank an intake runner's ability to set a charge into motion,

a swirl meter does not fully express turbulent flow (see "Rendering

2" below and "Turbulent Flow and Swirl" at

right). To simplify the comparison of swirl to turbulent flow,

cylinder heads with identical swirl readings from a flow bench's

swirl meter can have different behavior within the runner.

By behavior we are referring to an array of high and low static

pressure areas and the related high and low velocity areas.

Therefore, to only address swirl is to only look at a small

part of a more complex picture of turbulent flow.

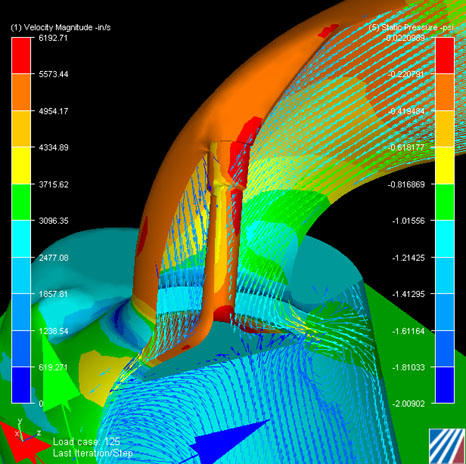

What this all really means

to the enthusiast staring at cylinder head swirl data is that

swirl defies the assignment of a set of hard and fast target

numbers for optimum performance. Edelbrock's, Rick Roberts

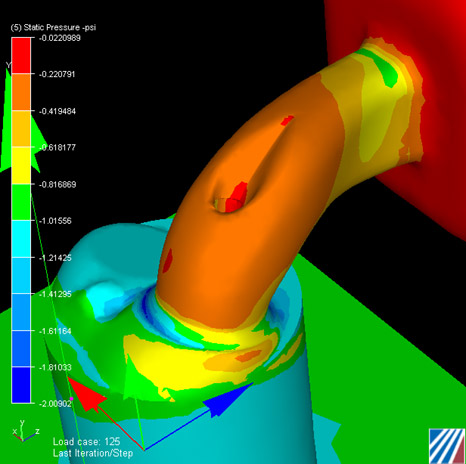

supplied these 3D renderings as an indication of just how

much action is really going on within a cylinder head. Clearly

it would take an entire education in Fluid Dynamics to intelligently

study these renderings, however it doesn't take much see that

static pressure and velocity take precedent over swirl at

this level of intake runner development.

Rendering

1: Static Pressure Within an Intake Runner Rendering

1: Static Pressure Within an Intake Runner

There is an inverse relationship between static pressure and

airflow. As static pressure increases, airflow drops. For

example, note the red "hotspot" around the valve

guide boss below. That area represents a high static pressure

point which correlates with low velocity.

Rendering

2: Static Pressure and Velocity Within an Intake Runner Rendering

2: Static Pressure and Velocity Within an Intake Runner

Note arrows that indicate

airflow velocity and direction. 3D renderings like this one

are use by Edelbrock to evaluate turbulent flow.

(Flow

and Swirl Testing) (Flow

and Swirl Testing)

|