|

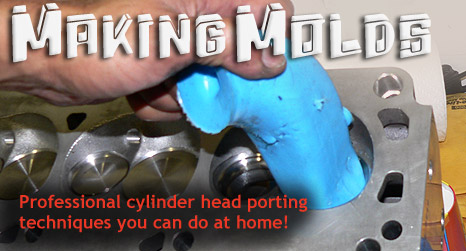

Have you ever wondered how professional

cylinder head porters and designers come up with their high-flowing

ports and runner shapes? Naturally it takes considerable experience

behind a die grinder and flowbench. But it also the right

tools and techniques. One of those techniques is making a

mold of the port. Port molds offer up a variety of analytical

opportunities by enabling the porter to see the entire runner

as a physical shape rather than as an empty cavity. The mold

of course also allows visualization of parts of the runner

that cannot be seen by looking into the port, such as the

short-side radius or transition around the valve guide. The

mold can be analyzed for shape, cut in various areas to measure

port dimensions, and even compared to molds taken earlier

or later in the process or versus other ports on the head.

It's a seemingly sophisticated technique that in reality is

very easy to do and only costs about $25 in materials. If

you port your own heads we highly recommend you take a mold.

If you port heads for customers a mold can be a great way

to periodically check your work on subsequent heads.

We've all used Silicone RTV as a gasket maker and have

marveled at how it takes a firm shape. That's basically

what we're using to make the mold. Silicone RTV (Room

Temperature Vulcanizing) mold kits are available from

hobby shops like TAP

Plastics. This kit is rated as "25 Shore A"

mold rubber - meaning it yields a low shrinkage, dimensionally

stable and elongation-resistant mold.

We've all used Silicone RTV as a gasket maker and have

marveled at how it takes a firm shape. That's basically

what we're using to make the mold. Silicone RTV (Room

Temperature Vulcanizing) mold kits are available from

hobby shops like TAP

Plastics. This kit is rated as "25 Shore A"

mold rubber - meaning it yields a low shrinkage, dimensionally

stable and elongation-resistant mold.

|

The 1lb kit is good for making one intake and one exhaust

port. The two parts are mixed right before you are ready

to pour the mold. The mix consists of a 9:1 ratio by volume

of base component (side A) and catalyst (side B). The

catalyst is added directly to white base container.

The 1lb kit is good for making one intake and one exhaust

port. The two parts are mixed right before you are ready

to pour the mold. The mix consists of a 9:1 ratio by volume

of base component (side A) and catalyst (side B). The

catalyst is added directly to white base container. |

The two parts must be mixed thoroughly until the material

is a light blue consistency throughout. White streaks

mean the base is not mixed well, this will result in a

mold with nooks and crannies.

The two parts must be mixed thoroughly until the material

is a light blue consistency throughout. White streaks

mean the base is not mixed well, this will result in a

mold with nooks and crannies. |

You only have about 30 minutes of working time before

the silicone starts to cure. A "green" catalyst

is also available which allows one hour of working time.

You only have about 30 minutes of working time before

the silicone starts to cure. A "green" catalyst

is also available which allows one hour of working time. |

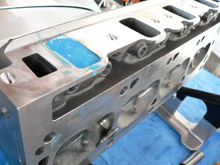

The recommended pour procedure is to transfer the silicone

mix into a paper cup and then poke a small hole in the

bottom. Position the head so the port faces upward. Note

that the valve should be placed in the head (without spring.)

This will keep the silicone from running out.

The recommended pour procedure is to transfer the silicone

mix into a paper cup and then poke a small hole in the

bottom. Position the head so the port faces upward. Note

that the valve should be placed in the head (without spring.)

This will keep the silicone from running out.

|

The cup and hole method allows for the air bubbles introduced

by the mixing process to dissipate. The cup also gives

better control in ensuring the entire cavity is filled.

The cup and hole method allows for the air bubbles introduced

by the mixing process to dissipate. The cup also gives

better control in ensuring the entire cavity is filled. |

Once the port is filled allow the silicone to cure for

6-8 hours. We prefer to let it sit overnight. Trying to

remove the mold prematurely can lead to tearing.

Once the port is filled allow the silicone to cure for

6-8 hours. We prefer to let it sit overnight. Trying to

remove the mold prematurely can lead to tearing.

|

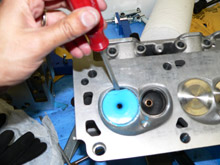

After the mold has cured we remove the valve and prepare

to extract the mold.

After the mold has cured we remove the valve and prepare

to extract the mold. |

Using a screwdriver we carefully separate the mold from

the port walls. Don't be too concerned about gouging the

mold, be more cautious that the screwdriver doesn't nick

up the valve seats or guides.

Using a screwdriver we carefully separate the mold from

the port walls. Don't be too concerned about gouging the

mold, be more cautious that the screwdriver doesn't nick

up the valve seats or guides. |

We like to spray silicone lubricant into the port to help

release the mold. There are also release agents available

made just for this purpose however we find the silicone

spray works well.

We like to spray silicone lubricant into the port to help

release the mold. There are also release agents available

made just for this purpose however we find the silicone

spray works well.

|

You can also spray through the guide plate boss to get

silicone lubricant thoroughly into the port.

You can also spray through the guide plate boss to get

silicone lubricant thoroughly into the port. |

If your valve guides protrude into the port you will most

likely need to use a blade and place a cut on the valve

head side of the mold. You only need to cut vertically

along half of the mold as shown, this will allow the mold

to move past the valve guide.

If your valve guides protrude into the port you will most

likely need to use a blade and place a cut on the valve

head side of the mold. You only need to cut vertically

along half of the mold as shown, this will allow the mold

to move past the valve guide. |

Use a screwdriver to carefully pry the silicone mold out

of the port through the combustion chamber.

Use a screwdriver to carefully pry the silicone mold out

of the port through the combustion chamber. |

The removal process takes a little patience and muscle.

You'll need to follow a sequence of prying, pulling, and

pushing from the port side. Spray silicone periodically

to lubricate the mold.

The removal process takes a little patience and muscle.

You'll need to follow a sequence of prying, pulling, and

pushing from the port side. Spray silicone periodically

to lubricate the mold. |

Once you get enough of the mold out you can grab hold

and yank it out of the runner.

Once you get enough of the mold out you can grab hold

and yank it out of the runner. |

The end result is precise 3D view of the inside of your

runner. As you can see it becomes very clear where the

restrictions are, and what areas need work. On both these

molds it is clear the pushrod passage pinches the port.

The end result is precise 3D view of the inside of your

runner. As you can see it becomes very clear where the

restrictions are, and what areas need work. On both these

molds it is clear the pushrod passage pinches the port.

|

|