|

Installing the Heads

We teamed up with Cole Cutler, CHI Motorsports' master engine

builder. Under his expertise we're able to show you (and learn

ourselves) the ins and outs of the 4.6L 2V. As you'll see

it is not as daunting as it seems, and while we worked with

the motor out of the car you can certainly perform the job

under the hood. If you do plan to tackle a head swap with

the motor in the car one tip is to pull the heads with the

stock manifolds attached, then swap them over to the new heads

before installing to the block. This will save from going

under the car to remove the manifolds.

We sourced a bone stock 4.6L 2V from a local salvage yard.

The car had just 7,800 miles before it was rear-ended

and totalled out. We began by pulling the stock plastic

intake. The injectors and fuel rails can all stay attached.

We sourced a bone stock 4.6L 2V from a local salvage yard.

The car had just 7,800 miles before it was rear-ended

and totalled out. We began by pulling the stock plastic

intake. The injectors and fuel rails can all stay attached. |

Tear down continues with removal of the valve covers followed

by the timing cover and chains. This is a Romeo engine

as evident by the 11 valve cover bolts per head and cam

girdles. More on the differences between Romeo and Windsor

engines on page 3.

Tear down continues with removal of the valve covers followed

by the timing cover and chains. This is a Romeo engine

as evident by the 11 valve cover bolts per head and cam

girdles. More on the differences between Romeo and Windsor

engines on page 3. |

The head bolts are removed and immediately thrown away.

You can't reuse TTY (torque to yield) hardware so don't

even try.

The head bolts are removed and immediately thrown away.

You can't reuse TTY (torque to yield) hardware so don't

even try. |

The stock heads can come off with the cams still bolted

down. Once on the work bench you'll want to pull off the

cam girdles and get the followers and lash adjusters as

they will be reused.

The stock heads can come off with the cams still bolted

down. Once on the work bench you'll want to pull off the

cam girdles and get the followers and lash adjusters as

they will be reused. |

We could have simply installed a new set of Ford torque-to-yield

TTY head bolts (#F5AZ6065A) on this motor, but we opted

for ArP studs (ARP# 256-4201 Buy

Now) for added clamping force. Plus unlike TTY bolts

the studs are reusable. At the time of writing this article

ARP did not have head bolts developed for these motors.

We could have simply installed a new set of Ford torque-to-yield

TTY head bolts (#F5AZ6065A) on this motor, but we opted

for ArP studs (ARP# 256-4201 Buy

Now) for added clamping force. Plus unlike TTY bolts

the studs are reusable. At the time of writing this article

ARP did not have head bolts developed for these motors.

|

These motors use multi-layered steel (MLS) head gaskets.

The Ford pieces cost $159 each! The Fel-Pro 9790-PT2 more

affordable choice at about $60 a piece. Coated with their

PermaTorque coating it will also seal up much better.

Unlike on pushrod Fords there is a distinct left and right

side. Note the pistons are below deck. This is "safe

mode" and is achieved with the crank key way placed

straight up at 12 0' clock. This will be important in

the cam installation phase to avoid bending valves.

These motors use multi-layered steel (MLS) head gaskets.

The Ford pieces cost $159 each! The Fel-Pro 9790-PT2 more

affordable choice at about $60 a piece. Coated with their

PermaTorque coating it will also seal up much better.

Unlike on pushrod Fords there is a distinct left and right

side. Note the pistons are below deck. This is "safe

mode" and is achieved with the crank key way placed

straight up at 12 0' clock. This will be important in

the cam installation phase to avoid bending valves. |

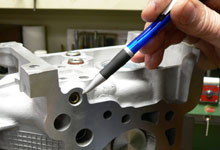

4.6L 2V cylinder heads are not side specific, however

the head you put on the driver-side of the motor must

have this galley plug installed in the back. Otherwise

you'll fire up with zero oil pressure and a big leak.

Once you install the plug mark the heads (D for Driver

side, etc.) so you don't accidentally install on the wrong

side.

4.6L 2V cylinder heads are not side specific, however

the head you put on the driver-side of the motor must

have this galley plug installed in the back. Otherwise

you'll fire up with zero oil pressure and a big leak.

Once you install the plug mark the heads (D for Driver

side, etc.) so you don't accidentally install on the wrong

side. |

The underside of both heads must have this plug installed.

Patriot installs this one for you, but it doesn't hurt

to double check.

The underside of both heads must have this plug installed.

Patriot installs this one for you, but it doesn't hurt

to double check. |

The springs supplied by Patriot are sufficient to .600"

lift however we opted to run the springs recommended by

Comp Cams (PN:26113-16). This spring works with all three

of there Xtreme Energy cams for PI heads.

The springs supplied by Patriot are sufficient to .600"

lift however we opted to run the springs recommended by

Comp Cams (PN:26113-16). This spring works with all three

of there Xtreme Energy cams for PI heads. |

The cam caps are machined specific to each side of the

cylinder head and cannot be interchanged. Mark them before

you remove them so they go back in the exact same location

and orientation.

The cam caps are machined specific to each side of the

cylinder head and cannot be interchanged. Mark them before

you remove them so they go back in the exact same location

and orientation. |

Lower the heads onto the block and install the bolts,

or in our case since we used studs, we'll install the

washers and nuts. Use oil or moly under the heads to get

a good torque reading.

Lower the heads onto the block and install the bolts,

or in our case since we used studs, we'll install the

washers and nuts. Use oil or moly under the heads to get

a good torque reading.

Note also that we have removed the cam "girdles"

from the heads (caps for Windsor Engine Plant heads).Their

locations are unique and cannot be interchanged along

the head or between cylinder heads. Mark them before you

remove! |

Cole's tip when building any motor is to have both heads

on the block and alternate your torqueing of the bolts/studs

between both heads to get even stretch on the block. Work

your way out from the inside pair of head bolts to the

outside, in steps from 30lb.ft. to 50lb.ft. to the final

spec. Remember if you do use the OEM TTY head bolts they

MUST be new, and you have to follow the stretch specification

outlined in the shop manual.

Cole's tip when building any motor is to have both heads

on the block and alternate your torqueing of the bolts/studs

between both heads to get even stretch on the block. Work

your way out from the inside pair of head bolts to the

outside, in steps from 30lb.ft. to 50lb.ft. to the final

spec. Remember if you do use the OEM TTY head bolts they

MUST be new, and you have to follow the stretch specification

outlined in the shop manual. |

|