|

From

Page 1

The Camshaft

Our initial plan with this engine was to run the stock

camshaft with 1.7:1 ratio rockers. However since we had

a brand new, Lunati hydraulic roller cam sitting in our

garage, we couldn't help but work it into this project.

The Lunati 51023 is actually supplied by Holley in their

"efi to carb" Systemax kit. For that reason

we weren't even sure if the cam would be a good match

for an EFI motor that need to meet emissions.

When we researched the cam a bit more, we learned that

Holley simply pulled the cam from Lunati's EFI lineup

of hydraulic roller cam. Lunati actually lists the 51023

as " Smooth idle hydraulic roller. Has good low end

and mid range torque and horsepower over stock. Power

range 2200-5500. "

The cam specifications are 215/224 duration at 0.050"

lift, and .522" lift on both the intake and exhaust valve.

The cam has a lobe separation angle of 112 degrees. Comparing

this cam to the popular FRPP alphabet soup cams, it falls

somewhere between a B (224/.480") and E (220/.498") cam.

The Lunati actually has more lift than these, but less

intake duration. The 112 separation angle and 215 intake

duration should keep emissions near stock at idle. We

figured it would be a smooth idling cam, with good mid

range (2500-4500) torque. The RPM intake should move the

torque band up 800 rpm or so and give us a good top end

charge. |

Assembly |

|

1.

The Lunati 51023 hydrualic

roller (215/224 duration / .522" lift) goes

in. We used a slight smearing of camshaft lube on

the lobes, and a large bolt threaded into the end

of the cam to help guide it into the bore without

damaging the bearings. |

2.

With the cam in place, the retaining plate is bolted

down. Be sure to orient the plate correctly, and

we like to use a dab of Loctite red to prevent the

bolts from backing out. Only torque them to 20lb.ft.

|

3.

The double-roller

timing gear and chain go on next. We installed the

cam straight up -ensuring the index marks on the

cam and crank gears are facing each other and lined

up perfectly. If it is off by a tooth, you must

remove the chain, turn the crank and cam, and reinstall.

One tooth is about 18 degrees- meaning the engine

wont start if you line it up incorrectly! |

4.

With the cam and timing gears installed, we turn

the motor over and install the oil pump, shaft and

pickup. We used a standard volume and pressure Melling

M68 oil pump, because our bearing clearances (.0015"

main and .002 rod) were on the tighter end of the

factory specs, and a high volume pump would just

rob horsepower. |

5.

It is important to check the clearance from the

pickup screen to the bottom of the oil pan. The

screen should be between 3/8" to 1/2"

from the pan bottom. Too close or too far can cause

oil starvation. You can measure as shown here by

using two rulers to measure the height of the pickup

from the pan mounting surface on the block... |

6.

...then measure the depth of the pan. Subtract the

height of the pickup from the depth of the pan,

and you have the distance the pickup will be from

the bottom of the pan once it is bolted on.

Be sure to add about 1/4" for the thickness

of the pan gasket. Better yet, when you measure

the height of the pickup, lay the pan gasket in

place to get an accurate measurement. |

7.

The other, easier, way to check for adequate pickup

clearance is to use a piece of clay or Playdough.

Place a 1" ball on the pickup, then install

the oil pan and gasket with a couple bolts to ensure

it is seated flush against the block. Then remove

the pan and carefully measure the thickness of the

clay. Shoot for 3/8" to 1/2" clearance.

|

8.

An interesting change made by Ford when they introduced

the EFI/roller 5.0L is the longer distributor drive

shaft (left) compared to earlier 289-302 distributors.

This creates a problem when you attempt to use the

hardened ARP oil pump driveshaft (top). The ARP

shaft has a barreled body with about 1" of

hex section at the top to engage the distributor.

With the longer distributor the retainer clip bottoms

out at the bottom of the hex portion and prevents

the distributor from seating properly against the

block. If you use the stock oil pump driveshaft

the clip is free to slide down as far as it needs

to, because the entire shaft is a hex shape. |

9.

There are two solutions, if you want to use

a heavy-duty oil pump drive shaft. The first is

NOT to buy the ARP (154-7904) shaft because it is

intended for the earlier 289-302 distributors. FRPP

sells a late-model specific heavy duty shaft which

has a longer hex portion, to allow the clip to slide

further down. (M6605B302)

The other option, if you already bought the ARP

shaft like we did, is to simply hack off the 1/2"

extension on the distributor shaft, as shown here.

It won't have any affect on the strength of the

distributor, and we're not sure why Ford made this

change in the first place. |

10.

We replaced the front seal in our "reconditioned"

timing cover and installed it on the block, using

a Fel Pro gasket and very light spread of silicone

RTV on both sides of the gasket to ensure a leak

free seal. |

11.

The oil pan is installed

next using the 5.0L specific one-piece rubber gasket.

You do not need to use any sealer with this type

of gasket, just ensure the end seal portions of

the gasket are properly seated into the timing cover

and rear main cap grooves.

|

12.

With the pan and timing

cover in place, we installed the harmonic balancer.

To keep costs down we bought a new stock replacement

50oz balancer ($100) rather than one of the better

constructed but more expensive brands. Spread a

thin film of moly or oil on the crank hub before

installing the damper to prevent it from binding.

Torque the bolt to 100 lb.ft. and be sure to install

the thick washer under the head of the bolt! |

| |

|

(More

assembly.) (More

assembly.) |

|

|

|

|

|

|

|

|

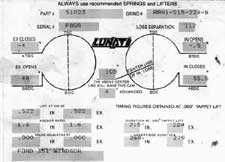

Cam Selection

We choose the Lunati 51023 camshaft for it's mild but EFI

intended specfications. (View

large)

|

Planning ahead

For under $75 we gathered everything we'd need to assemble

the complete engine on the stand, minus valve covers (someone

beat us to them). We spent the rest of the day cleaning the

parts and then painting them with satin black and Eastwoods

"Detail Gray". The parts looked better than new

and we saved a ton of time, work and aggravation during the

day of the actual engine swap because we weren't relying on

dirty parts coming off the motor in car. |

|