Our

initial inclination was to open up the parts catalog and order an off the

shelf torque converter. But after hearing some horror stories about such

converters not performing well and even falling apart, we decided to get

some recommendations. We noticed a few cars at our local track with Emerald

Torque Converters decals, and considering they were local (Walnut Creek,

CA) we decided to give them a call.

Emerald asked us details about our car, gearing, and engine, and based on

our responses they suggested a 2800 stall non-lockup converter. The cool

thing about Emerald is that their converters are built to the customers

specific requirements, they don't try to fit you with a generic converter.

We spent a morning at Emerald's shop installing the

converter, and the following weekend we took the car out to the strip.

Our initial impressions could be summed up with a huge grin on our face.

A stock 5.0 engine is torquey as it is...throw in a converter and you may

as well buy stock in Goodyear. The stock 225-60-15 tires are simply ill

suited for the immediate torque shock. With the stock converter the torque

builds gradually and max torque doesn't hit the tires until the car is in

motion. With the new converter, stabbing the throttle just halfway results

in tire spin. It took a few stoplights to teach ourselves to leave softly.

Other than the feeling we've added 50 more lb.ft. of torque to the motor,

the converter has no major side effects in terms of driveability. Because

this converter does not lockup there is about 200-300 rpm worth of slippage

in drive and overdrive. With the stock converter the engine at 65 mph would

turn at approximately 2200 rpm, we're now noticing it turns closer to 2500

rpm. While you'd expect some loss in fuel economy due to the increased rpm,

our mileage in fact has remained exactly the same. We figure this is because

we're not having to downshift from OD to D as often in order to accelerate

and pass. The non-lockup converter reacts so fast in overdrive that there

is very little need to downshift at freeway speeds.

One of the

side effects of a higher stall converter is dampening of the shifts. With

the stock converter and a TransGo shift kit we could bark the tires during

1-2 and 2-3 upshifts. With the new converter the transmission still shifts

fast, but the shifts are softer than grandmas Cadillac.

We

contacted TransGo to see if there was a valve body modification which

would bring back some of the hard shifting we were used to. They recommended

we upgrade the 1-2 valve with the "blue" spring (included in

their shift kit). So we dropped the pan and valve body and swapped the

green spring for the blue one. This resulted in bringing back the 1-2

bark at wide open throttle. We also installed a transmission fluid cooler,

since the higher stall and slippage generate more heat in the transmission,

which can also lead to soft shifts. If we really wanted hard shifts in

all gears, the only other solution would be to rebuild the transmission

with specific modifications to the fluid passages. We'll live with it

for now.

|

|

| Upgrade

the 1-2 valve with the "blue" spring in the TransGo shift

kit to firm up the 1-2 shift. |

High

stall converters generate heat, which is the enemy of automatic transmissions.

Install a fluid cooler! |

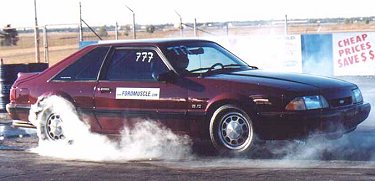

We took

the car out to Sacramento Raceway to get some objective results from the

converter upgrade. Unfortunately the weather conditions were worse that

when we had baselined the car with the stock converter. Temps were in

the high 90's, humidity was high, and barometric pressure was low (mid

29's) - about the worst conditions for racing.

Nevertheless the car gained a tenth over its best ET (13.84@97.5

versus 13.94@99.7) with the stock converter. We were down 2mph, but

so were most of the other cars. We figure in better conditions there is

at least another tenth in the converter. Keep in mind, this is launching

easy on street tires, with 60 ft. times in the 2.0 range. With slicks

and a full throttle launch a couple more tenths off the ET can be expected.

(see timeslip log for

Project '88)

|

|

| We

took the '88 LX to Sacramento Raceway to test out the new converter.

The car ran 13.84, a tenth faster than with the stock converter, in

very hot weather and on stock radials. There is at least another tenth

or two with cooler air and slicks. |

| Making

Torque |

Gary

Mladinich is the brains behind Emerald Converters. We spent a couple

hours with Gary discussing what makes Emerald Converters far superior

to any of the off the shelf brands. Gary spends a considerable amount

of time upfront ensuring the converter matches the customers stall

speed requirements. The size, number, and pitch of the vanes in the

turbine, impeller, and stator are major factors in determining the

characteristics of a stall converter. Two converters which are rated

at the same stall speed may feel and react completely different based

on how they are constructed. Gary

Mladinich is the brains behind Emerald Converters. We spent a couple

hours with Gary discussing what makes Emerald Converters far superior

to any of the off the shelf brands. Gary spends a considerable amount

of time upfront ensuring the converter matches the customers stall

speed requirements. The size, number, and pitch of the vanes in the

turbine, impeller, and stator are major factors in determining the

characteristics of a stall converter. Two converters which are rated

at the same stall speed may feel and react completely different based

on how they are constructed.

Gary pointed out also how the internals of many aftermarket converters

are no stronger than stock. While they may achieve the stall speed,

the internals are not meant to handle the power and the converter

is prone to fail.

Building

a powerful converter means having the right components and cores on

hand. Gary explained that the typical 9" and 9.5" (245mm)

converters are based on cores from GM front wheel drive 4T60 transmissions.

They are preferred because they come in eight different impeller vane

angles, and are also a good physical size for obtaining higher stall

speeds. Building

a powerful converter means having the right components and cores on

hand. Gary explained that the typical 9" and 9.5" (245mm)

converters are based on cores from GM front wheel drive 4T60 transmissions.

They are preferred because they come in eight different impeller vane

angles, and are also a good physical size for obtaining higher stall

speeds. |

|

|

|

The

vanes of stock and many off the shelf converters are simply

slip-fit into place. Fluid under high centrifugal force causes

the vanes to flex or bend, resulting in a loss torque transfer,

and eventual breakage or bending.

Furnace

brazing (top right) is a popular feature on many converters,

but the vanes can still be flexed easily. |

|

|

Emerald

converters feature tig welded vanes on both the impeller and

turbine for the ultimate in strength and resistance to flex.

For high power applications Emerald offer a double bladed turbine

upgrade. |

|

|

|

Precisely

machining clearances within the converter can make the difference

between a poorly reacting converter and one that snaps you back

in your seat at the slightest tip of the throttle.

|

|

|

|

|

| Other

strengthening features include a hardened steel impeller hub,

billet front cover, anti ballooning flange (shown), and hardened

stator sprague and race. |

|

A

sprague eliminator is also available for all-out race cars requiring

constant torque multiplication. |

|

|

|

|

The

converter halves are precision welded using a robotic welder.

|

|

The

finished converter is checked for leaks and balanced, then shot

with the trademark Emerald green paint.

|

|

|

Contact:

Emerald Torque Converters

2040 North Main St. # 16

Walnut Creek, CA 94596

Phone: 925-934-8070

Fax: 925-945-0650

|

|