|

by Jon Mikelonis

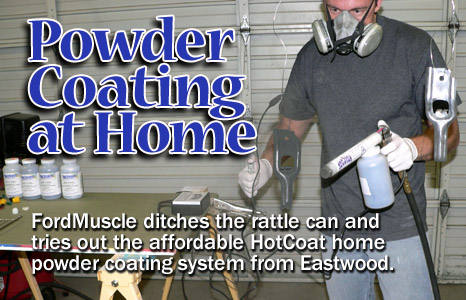

If you've never heard of powder coating,

before reading any further do a google search and discover

the advantages of the youngest surface finishing technique

in use today. Once you are convinced that a more

durable and scratch resistant finish is what you desire, this

step-by-step article will show you how you can get started

powder coating in your own

garage.

Powder coating eliminates the use of

the "liquid carrier" that is used in normal aerosol

painting by applying paint electrostatically then baking or

curing the part in an oven. The powder or paint used in powder

coating is positively charged and essentially dusted onto

a negatively charged metal

part. Yes, powder coating only works only on metal material

such as steel, zinc, and aluminum. The result is a harder,

more abrasion resistant finish that is very tolerant of solvents,

greases, and oils. In my opinion, powder coating is cleaner

too since the entire process from prep to bolt-on is not as

long and does not require multiple coats. With powder coating,

"overspray" is 100% dry making it a snap to clean

up.

For the DIY auto enthusiast the greatest

value in powder coating is found

with parts that are both focal points and subject to a tough

environment.

While joe average doesn't consider what's under the hood a

focal point,

you and I do. And that's just about everybody in my book.

Combine the focal aspect of your motor compartment with the

fact that most underhood parts are exposed to high temperatures

and paint-eating fluids and there's no better place to get

started powder coating. Besides, if you're after the perfect

satin black finish that doesn't rob your ride of the dignity

it deserves, Eastwood's semi-gloss black powder will give

you exact results everytime. That is, if you prep your parts

using patience and

knowledge. Let me show you how it works. The Eastwood Company

has made it very simple

Here's a shot showing the primary items required to get

started powder

Here's a shot showing the primary items required to get

started powder

coating. A powder coating gun kit, compressed air, some

good candidates for coating, and a dedicated parts oven.

Depending on the size of your parts, a toaster oven will

perform just fine.

|

|

For the purposes of this article I chose some spare radiator

tie downs

For the purposes of this article I chose some spare radiator

tie downs

that had been through my usual archaic restoration process

of strip,

rattle can, and premature installation. |

| |

|

|

|

Preparation of any part to be coated is critical. Even

more so with powder coating since a speck of paint,

dirt, or grease on the items you

Preparation of any part to be coated is critical. Even

more so with powder coating since a speck of paint,

dirt, or grease on the items you

intend to finish will prevent the powder from bonding

to the dirty area. Here I started with some Jasco to

remove old paint.

|

|

What wouldn't come off with Jasco, I hit with a drill

and wire wheel. I

What wouldn't come off with Jasco, I hit with a drill

and wire wheel. I

was sure to thoroughly clean all the Jasco from the part

before I spun any

residual onto my bare forearms. That stuff burns. Whoooh. |

| |

|

|

Once there were no visible signs of paint, grease, or

dirt, I wiped the

Once there were no visible signs of paint, grease, or

dirt, I wiped the

tie downs with Eastwood's "Pre". It's a solution

designed to lift off any

remaining contaminants that might prevent the dry powder

from bonding upon application. |

|

This is how parts should look before you bust out the

gun.

This is how parts should look before you bust out the

gun. |

| |

|

|

The Eastwood HotCoat Deluxe Kit inlcudes some safety wire

for hanging

The Eastwood HotCoat Deluxe Kit inlcudes some safety wire

for hanging

parts.

|

|

I cut off a couple 3 foot segments and suspended the tie

downs from the

I cut off a couple 3 foot segments and suspended the tie

downs from the

rafters.

|

| |

|

|

Powder coating with this kit does not require a large

compressor or

Powder coating with this kit does not require a large

compressor or

high pressures. I dialed mine down to 8 psi to prepare

it for powdering. A

portable air tank or small compressor will work just fine.

The instructions say 5-8 psi is sufficient. |

|

The kit suggests filling one of the supplied containers

1/3 full with

The kit suggests filling one of the supplied containers

1/3 full with

powder to promote a good flow. |

|