| |

|

|

|

|

| |

Stage 2: K-Member Brace

Continuing on with the objective of transforming the front-half

of the unibody into a rigid box, we turn our attention to the

under side of the car. The K-member is a major chassis component

to which the engine and all front steering and suspension is

mounted to. As a result it also take quite a bit of abuse and

is subject to twisting and flexing.

Aftermaket companies, such as Maximum Motorsports, have developed

a simple brace to help strengthen the K-member. A "four

point" tubular K-member brace is the best bet, but clearance

with aftermarket headers could limit you to a two point brace.

This Maximum Motorsports photo

shows how the 4-point brace mouns to a K-member.

|

The tubular brace utilizes existing

holes in the K-member. |

On cars with the factory h-pipe

in place, slight grinding of the heat-sheild is necessary

for clearance. |

Once on the car,

the K-brace fits close to the chassis and does not decrease

ground clearance. |

|

Stage 3/4: Subframe Connectors

and Torque Box Reinforcements

To really have a stable platform in a unibody car the front

and rear subframes need to be tied together, and if you intend

to go that far in FOX bodied Mustang then you should address

the torque boxes as well.

Torque box reinforcements by Wolf

Race Craft. |

The attaching points for the rear

axle control arms are called torque boxes and they are simply

bent pieces of sheet metal pinch-welded together and to the

body. Once power is increased and the chassis starts enduring

dragstrip launches or road course g-forces the torque boxes

can bend, crack and even tear if you add sticky tires to the

equation.

After over a hundred hard launches on sticky tires the torque

boxes on GMII surprisingly showed no signs of major distortion,

but, as the need for speed mandates more power we thought it'd

be a good idea to reinforce them now rather than later. Furthermore

because subframe connectors weld over part of the torque box,

it makes sense to weld up the torque boxes at the same time.

More

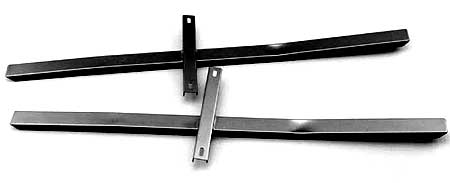

Subframe connectors from Maximum

Motorsports. Made of 1” x 2” rectangular tubing,

with .120” wall thickness. The cross bar serves to

reinforce the crack-prone area of the floor pan where

the seats attach. MM also makes a longer "full length"

connectors that extends farther up the firewall. |

Continue

|

|

|

|

|

|

|

|