|

|

|

|

| The

bone stock '88 5.0 (mass air) has 130K miles, and has run

a best of 13.89@99.5

mph. The head and intake upgrade should land us in the mid-13's,

on radials. |

Late model cars have alot of electrical and vacuum connections,

which can make the job intimidating. We recommend taking some

pictures before disassembly, so you know where to put everything

back. |

Removing

the heads requires draining the coolant and oil, and depressurizing

the fuel lines using the schrader valve located on the fuel

rail. We also disconnected the h-pipe from the headers. |

The

EGR coolant lines,throttle cable bracket, and a few vacuum

lines need to disconnected before the upper intake can be

lifted off. |

|

|

|

|

| With

the upper off, we've got access to the fuel rails and lower

intake. Remove the distributor before attempting to remove

the lower. |

We

didn't have the proper fuel line disconnect tools, so we simply

swung the fuel rail and injectors over to the side. We also

removed the AC compressor from its bracket and set it aside,

without disconnecting any of its hoses. |

With

the lower intake off, the heads can be unbolted and lifted

off. |

The

sludge and crud buildup is typical for a high-mileage motor

that has never been apart. This is good opportunity to clean

it all out. We even found remnants of a bee in one intake

port!

|

|

|

|

|

| The

most critical part of the whole process is cleaning the head

surface and intake valley. We used a shop vac to vacuum up

the coolant in the bores. Then using gasket remover and carb

cleaner, we methodically cleaned everything. |

About

two hours later, we've got a block surface so clean you could

eat off it. But then you'd have to clean it again...so don't!

As a final prep of the surface, wipe off any grease with paint

thinner or similar degreaser. |

With

the locating dowels in place, the new head gaskets (Fel Pro

8548-PT2) are laid down, taking care that they are oriented

properly. Remember, small block Fords only have coolant passing

through the gasket at the rear of the block. Most gaskets

have "FRONT" stamped in them to remind you. |

With

the gaskets down, the Holley heads are set in place. |

|

|

|

|

| It's

a good idea to use new ARP head bolts whenever replacing heads.

Use RTV sealer on the lower bolts since they pass through

water jackets. |

Always torque head bolts in sequence, beginning with the center

head bolts and alternating to the outer bolts. Torque in steps

(i.e. 30 lb.ft, 60 lb.ft, and 80 lb.ft.) |

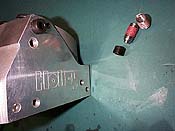

Due

to the raised exhaust ports, the AIR holes in Holley head

are also .400" higher. Since this would cause a problem

with the accessory brackets, the systemax heads come with

another threaded hole in the stock location. To block the

AIR holes in the front of the heads you'll need a 5/8"

pipe thread plug, available at most hardware stores. The Ford

threaded bushings using in the stock heads will not work (shown

upper right.) |

The

raised AIR holes requires that the AIR tube be lengthened

about 1". Holley instructs you to use a hacksaw to cut

the tube. |

|

|

|

|

| Then

use the included compression fittings to rejoin the two tubes.

The AIR tube is now the correct length and can be bolted to

the back of the heads. Holley however neglects to mention

the stock bolts to hold the tube to the heads will not work,

as they are too long. You'll need to go to the hardware store

with the bolt in hand and find one about 1/2" shorter

in the correct thread size. |

The

headers get bolted in place next. It's always a good idea

to use antiseize or Teflon tape whenever threading steel fasteners

into aluminum. |

We

had replaced the stock restrictive headers with Dynomax

shorties a while back. The 1 5/8" equal-length primaries

will be a perfect match for the well flowing Systemax exhaust

ports. |

Rather

than use the stock pedestal mount rocker arms, we opted to

convert to the more reliable stud-mount rocker arms. To do

this we used Crane's pedestal to stud conversion kit (part

no. 26655-16). The kit simply bolts to the pedestal mounts

without requiring any machine work, and enables the use of

a standard 3/8" stud mount roller rockers. |

|

|

|

Holley recommends the Champion plug on the right. Unfortunately

the large 13/16" socket size on this plug interferes

with our header flanges. We opted to use the Autolite 5184

plug on the left, which has the same gasket seat, reach, and

heat range. |

| Installation

of the Crane conversion kit is very simple. Rather than a

conventional hardened steel guideplate, the kit uses a plastic

insert to guide the pushrod. This allows the use of the stock,

non-hardened pushrod. |

The

Holley heads require a slightly shorter pushrod than stock.

Holley recommends a 6.400" pushrod, however we measured

and deemed a 6.375" to be a perfect fit, and also a more

common size. We picked up Crane's 36623-16 for about $80.

|

The

1.6:1 roller tip rockers go on next. Setting lifter preload

with stud mount rockers is easier than than fussing with the

shims and torque settings for pedestal mount rockers. Simply

turn the hex nut until there is no play in the pushrod, then

give it another half-turn and snug down the allen lock. You

still need to make all preload adjustments with the lifter

on the base circle of the cam. |

|

|

EXPLORER

INTAKE INSTALLATION >>

|

| Shown

here is the AC / PS bracket mounted on the stock head. For

whatever reason the bracket would not bolt up straight to

the Systemax head. We had to open up the holes to the next

drill size in order to solve the problem. |

Another

headache with the Holley heads is the fact the stock '88-'92

valve covers do not fit. The reinforcement ribs along the

inside of the cover interferes with the valve springs. We

had to grind all these flat to get the covers to work. Aftermarket

valve covers will work, but require a spacer between the lower

an upper intake in order to clear the throttle linkage. |

|

|