Head Assembly

With the heads milled and cleaned, we're ready to assembly

the hardware. As mentioned earlier, we opted to get most

of the valve train hardware from Crane. This ensures we

get the correct springs, retainers, etc. to match our

cam specs. One of the most frustrating things to experience

is a valvetrain that doesn't go together right, or springs

that float when you go to push the engine. Sticking with

the manfacturers matched components all but ensures success.

Solid roller cams require the use of extremely high spring

pressures. We're using Crane (Part No. 99893) double springs

with 165 lbs. seat, and 426 lbs. open pressure; with an

installed height of 1.750". Installed height is a

critical factor when installing any set of valve springs.

The pressure rating of the spring will vary with height,

which directly affects its ability to control the valves.

More often than not you will need to use shims to meet

the installed height specs for your springs. Shims come

in three heights, 0.015", 0.030", and 0.060".

However shims come in a variety of inner and outer diameter

combinations; so it is extremely important that you select

the correct shims. In the photo series below we'll take

you though the process of correctly setting up the valve

springs and related components on a cylinder head.

| Setting up

the Valve Springs |

Start by checking the installed height. Measure

with a small macinists rule or spring micrometer

from spring seat to underside of the retainer. Add

shims to decrease space, or machine the seat to

increase. The objective is to meet the specification

listed on the cam card.

Start by checking the installed height. Measure

with a small macinists rule or spring micrometer

from spring seat to underside of the retainer. Add

shims to decrease space, or machine the seat to

increase. The objective is to meet the specification

listed on the cam card. |

Only use hardended/heat treated shims. Otherwise

you'll end up with shrapnel

in your motor. The correct shim will properly locate

around the valve guide, and/or fit spring seat,

as well as be the correct diameter for the spring

being used. Shims usually come in 0.015", 0.030",

0.060" thicknesses.

Only use hardended/heat treated shims. Otherwise

you'll end up with shrapnel

in your motor. The correct shim will properly locate

around the valve guide, and/or fit spring seat,

as well as be the correct diameter for the spring

being used. Shims usually come in 0.015", 0.030",

0.060" thicknesses. |

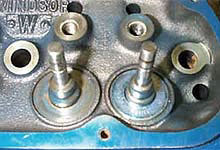

The majority of aftermarket heads come with guideplates

and screw-in studs. This set-up is offers increased

stability, strength, and adjustbility over rail

type or pedestal mount rockers. Whenever possible

we recommend stepping up to 7/16" studs rather

than 3/8" for maximum strength. Some heads

(such as Worlds) require using sealer on the stud

threads as the holes are open to the head coolant

passages.

The majority of aftermarket heads come with guideplates

and screw-in studs. This set-up is offers increased

stability, strength, and adjustbility over rail

type or pedestal mount rockers. Whenever possible

we recommend stepping up to 7/16" studs rather

than 3/8" for maximum strength. Some heads

(such as Worlds) require using sealer on the stud

threads as the holes are open to the head coolant

passages. |

There are two major types

of oil seals. The "umbrella"

seal rides the valve stem, while the Teflon

seals fits snug over the guide and "scrapes"

the oil off the valve stem. Teflons are better at

controlling oil through the valve guide, and more

importantly they clear double springs and high-lift

cams. Teflon seals

come in 0.500" ID or 0.531" ID, so the

valve guide outer diameter may have to machined

to this size to allow the seal to "cap"

the guide.

There are two major types

of oil seals. The "umbrella"

seal rides the valve stem, while the Teflon

seals fits snug over the guide and "scrapes"

the oil off the valve stem. Teflons are better at

controlling oil through the valve guide, and more

importantly they clear double springs and high-lift

cams. Teflon seals

come in 0.500" ID or 0.531" ID, so the

valve guide outer diameter may have to machined

to this size to allow the seal to "cap"

the guide. |

The valve springs are installed

with this handheld spring compressor (Craftsman

brand). Be sure to wear eye protection when handling

compressed valve springs, they hold quite a bit

of force.

The valve springs are installed

with this handheld spring compressor (Craftsman

brand). Be sure to wear eye protection when handling

compressed valve springs, they hold quite a bit

of force. |

The

final step is to check the coil springs for binding.

Install pushrods and rocker arms for at least one

cylinder. Rotate the crank until the valve is fully

open, and with a feeler guage check for at least

0.060" clearance between the center two coils. The

final step is to check the coil springs for binding.

Install pushrods and rocker arms for at least one

cylinder. Rotate the crank until the valve is fully

open, and with a feeler guage check for at least

0.060" clearance between the center two coils.

|

|

(Intake Selection and Preparation)

(Intake Selection and Preparation) |

| |

|

|

|

|

|