The included WOT throttle switch uses the same type of

bracket used for mounting the fuel and nitrous solenoids.

The included WOT throttle switch uses the same type of

bracket used for mounting the fuel and nitrous solenoids. |

|

I planned to mount the WOT switch and bracket on the rear

driver's side carburetor stud. Turns out I needed a longer

stud to make it work. I pulled the carb and added a single

1-1/2" carb stud in this location.

I planned to mount the WOT switch and bracket on the rear

driver's side carburetor stud. Turns out I needed a longer

stud to make it work. I pulled the carb and added a single

1-1/2" carb stud in this location. |

| |

|

|

It wasn't pretty but it was solid. The bracket required

a good twist and turn to work. You can see that at WOT,

the carb linkage would make contact with the WOT switch

arm.

It wasn't pretty but it was solid. The bracket required

a good twist and turn to work. You can see that at WOT,

the carb linkage would make contact with the WOT switch

arm. |

|

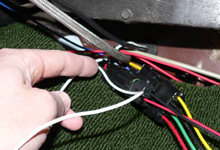

Remember this shot from the bottle heater section? The

paired red and white wire from the primary arming switch

would come into play now.

Remember this shot from the bottle heater section? The

paired red and white wire from the primary arming switch

would come into play now. |

| |

|

|

Here's the pair routed from the console and just above

the passenger floor board.

Here's the pair routed from the console and just above

the passenger floor board. |

|

I threaded the white wire through the firewall and headed

for the WOT switch.

I threaded the white wire through the firewall and headed

for the WOT switch. |

| |

|

|

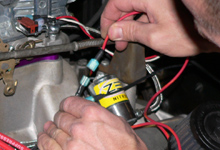

This shot shows the white wire from the primary arming

switch attached to "Post 4" on the WOT switch.

The

red wire from the primary arming switch was connected

to a 12V Key On terminal on my auxiliary terminal block.

This shot shows the white wire from the primary arming

switch attached to "Post 4" on the WOT switch.

The

red wire from the primary arming switch was connected

to a 12V Key On terminal on my auxiliary terminal block. |

|

Now it was time to wire the fuel and nitrous solenoids.

Neither solenoid had specific polarity. Either wire on

each solenoid can serve as that solenoid's ground wire.

Now it was time to wire the fuel and nitrous solenoids.

Neither solenoid had specific polarity. Either wire on

each solenoid can serve as that solenoid's ground wire. |

| |

|

|

I joined one wire from each solenoid together with a single

wire and ring terminal for grounding on the engine block.

I joined one wire from each solenoid together with a single

wire and ring terminal for grounding on the engine block. |

|

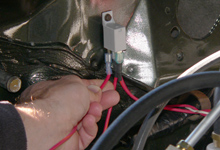

Here I found a suitable firewall location for the included

and necessary relay.

Here I found a suitable firewall location for the included

and necessary relay. |

| |

|

|

I made up this red wire to run from "Post 1"

on the WOT switch...

I made up this red wire to run from "Post 1"

on the WOT switch... |

|

...to "Post 1" on the relay.

...to "Post 1" on the relay. |

| |

|

|

Next, I joined the two remaining solenoid wires for a

run to "Post 3" on the relay.

Next, I joined the two remaining solenoid wires for a

run to "Post 3" on the relay. |

|

The relay needed 12V straight from the battery.

The relay needed 12V straight from the battery. |

| |

|

|

That same 12V wire required a 30 amp fuse.

That same 12V wire required a 30 amp fuse. |

|

The now fused 12V battery wire was connected to "Post

5" on the relay.

The now fused 12V battery wire was connected to "Post

5" on the relay. |

| |

|

|

I made up a ground wire for the relay...

I made up a ground wire for the relay... |

|

...and connected it to "Post 2" on the relay.

I used the same engine block ground location that I used

for grounding the solenoids.

...and connected it to "Post 2" on the relay.

I used the same engine block ground location that I used

for grounding the solenoids. |

| |

|

|

With basic wiring done, it was time to test the solenoids.

Agani, no need for the nitrous bottle to be opened or

the car to be running.

With basic wiring done, it was time to test the solenoids.

Agani, no need for the nitrous bottle to be opened or

the car to be running. |

|

With the key in the on position and the primary arming

switch on, I manually depressed the WOT switch and confirmed

that both solenoids opened up. The "click" was

easily identifiable.

With the key in the on position and the primary arming

switch on, I manually depressed the WOT switch and confirmed

that both solenoids opened up. The "click" was

easily identifiable. |

The Mallory box specifies this violet wire originating

from the connector shown as the RPM window switch wire.

The Mallory box is a "ground" based system.

This means, the switch is active when it is grounded.

Confusing? Let's show you how easy it is.

The Mallory box specifies this violet wire originating

from the connector shown as the RPM window switch wire.

The Mallory box is a "ground" based system.

This means, the switch is active when it is grounded.

Confusing? Let's show you how easy it is. |

|

I temporarily ran this long red wire (the one I connected

to the violet wire in caption 1) outside the car and toward

the firewall mounted relay I worked with in the previous

wiring section.

I temporarily ran this long red wire (the one I connected

to the violet wire in caption 1) outside the car and toward

the firewall mounted relay I worked with in the previous

wiring section. |

| |

|

|

I pulled the relay grounding wire from "Post 2"

that I had made up in the previous wiring section...

I pulled the relay grounding wire from "Post 2"

that I had made up in the previous wiring section... |

|

...and simply replaced it with the single RPM window switch

wire from the Mallory HyFire ignition box.

...and simply replaced it with the single RPM window switch

wire from the Mallory HyFire ignition box. |

| |

|

|

For testing purposed, I set the RPM window switch to activate

a 1500RPM and shut off at 2000RPM.

For testing purposed, I set the RPM window switch to activate

a 1500RPM and shut off at 2000RPM. |

|

With the motor running, I slowly ran the throttle from

idle to 2500 RPM while manually depressing the WOT switch.

I clearly heard two clicks, the sign of a safe nitrous

system.

With the motor running, I slowly ran the throttle from

idle to 2500 RPM while manually depressing the WOT switch.

I clearly heard two clicks, the sign of a safe nitrous

system. |