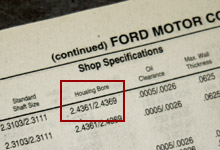

Superior grinds and hones the big end of the rod to the

high end of the manufacturer's spec. In this case, 2.4369"

Superior grinds and hones the big end of the rod to the

high end of the manufacturer's spec. In this case, 2.4369" |

|

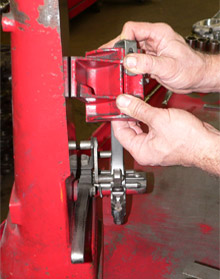

With the proper honing mandrel in place, the rod and cap

assemblies were run on this rod reconditioning machine.

With the proper honing mandrel in place, the rod and cap

assemblies were run on this rod reconditioning machine. |

| |

|

|

This gauge verifies that the honed rod and cap assemblies

meet the specification. All eight sets were processed

on the rod reconditioning machine.

This gauge verifies that the honed rod and cap assemblies

meet the specification. All eight sets were processed

on the rod reconditioning machine. |

|

It was time to move on to the small end of the rod. First

step was to verify the pin diameters.

It was time to move on to the small end of the rod. First

step was to verify the pin diameters. |

| |

|

|

From the micrometer to the rod reconditioning machine,

the pin diameter figure is transferred.

From the micrometer to the rod reconditioning machine,

the pin diameter figure is transferred. |

|

Press fit pins should have a .0010 to .0015 interference

fit with the rod. Each rod's small end is measured to

determine the amount of honing necessary to create the

required interference fit.

Press fit pins should have a .0010 to .0015 interference

fit with the rod. Each rod's small end is measured to

determine the amount of honing necessary to create the

required interference fit. |

| |

|

|

One of the eight rod's small end is honed accordingly.

One of the eight rod's small end is honed accordingly. |

|

A honing mandrel verifies the piston's pin bore is sized

appropriately.

A honing mandrel verifies the piston's pin bore is sized

appropriately. |

| |

|

|

Once all eight rod and cap assemblies were off the reconditioning

machine, it was on to balancing. Here, Augie finds the

assembly with the lightest big end.

Once all eight rod and cap assemblies were off the reconditioning

machine, it was on to balancing. Here, Augie finds the

assembly with the lightest big end. |

|

The lightest big end was 622 grams. The remaining seven

assemblies were ground on the cap to reach the same weight.

The lightest big end was 622 grams. The remaining seven

assemblies were ground on the cap to reach the same weight. |

| |

|

|

The scale is tared with 622 grams on the deck. Now each

rod assembly is measured to determine the lightest small

end. The lightest small end in our case was 216 grams.

The scale is tared with 622 grams on the deck. Now each

rod assembly is measured to determine the lightest small

end. The lightest small end in our case was 216 grams.

|

|

The remaining seven assemblies are ground on the small

end to reach 216 grams.

The remaining seven assemblies are ground on the small

end to reach 216 grams. |

| |

|

|

Here's one finished rod assembly.

Here's one finished rod assembly. |

|

With the rod and cap assemblies ready for pistons, we

needed to balance them as well. The lightest piston is

found and a ball mill removes material on the underside

of the remaining seven to create a matched set.

With the rod and cap assemblies ready for pistons, we

needed to balance them as well. The lightest piston is

found and a ball mill removes material on the underside

of the remaining seven to create a matched set. |

| |

|

|

A rod heater expands each rod's pin bore.

A rod heater expands each rod's pin bore. |

|

The expansion allows the pin to be fitted. When the rod

cools, the rod takes a bite onto the pin. The process

was repeated for the remaining seven assemblies.

The expansion allows the pin to be fitted. When the rod

cools, the rod takes a bite onto the pin. The process

was repeated for the remaining seven assemblies. |

| |

|

|

This twist fixture verifies the trueness of the rod and

piston assemblies.

This twist fixture verifies the trueness of the rod and

piston assemblies. |

|

Twisted or bent rods will show themselves as gaps between

the stationary and rotating machined surfaces of the fixture.

Twisted or bent rods will show themselves as gaps between

the stationary and rotating machined surfaces of the fixture. |

| |

|

|

That's right, if a rod is bent or twisted, a little leverage

and patience will bring the rod back to a true state.

Better left to the experts!

That's right, if a rod is bent or twisted, a little leverage

and patience will bring the rod back to a true state.

Better left to the experts!

|

|

|