|

Air-Fuel Meter Shootout (continued)

As previously discussed, air/fuel data is most useful when

correlated with other key parameters like throttle position,

manifold absolute pressure, and RPM. And this sort of correlation

absolutely requires data logging. So, even though all of these

units feature useful real-time displays, the most important

parameters are response time and the quality of the logging

solution. Response time is critical because it's possible

to have accurate data, but, due to high latency/delay, the

data is essentially in the wrong

column of your fuel map.

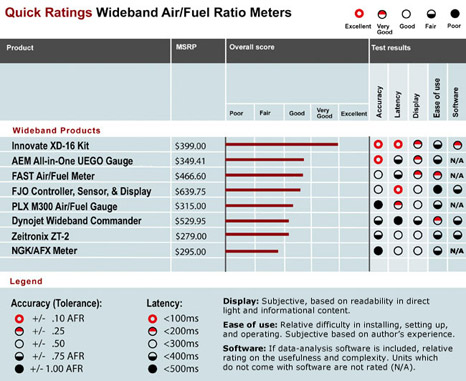

Results - At a Glance

Listed below, from A to Z, are the eight meters we tested.

All use the Bosch LSU4 wideband oxygen sensor. There was a

surprising amount of variation between the various units,

in terms of both accuracy and response time. We also rated

the ease of use, display, and included software. The participants

were AEM, Dynojet, FAST, FJO, Innovate, NGK, PLX, and Zeitronix.

AEM

The AEM unit was accurate during our tests, but with no

real data logging capability, of limited usefulness for

actual tuning. It was average for response time. |

AFX (NGK)

The NGK unit exhibited low scores for accuracy, and it

was missing the required wire for analog output. It does

not have data logging capabilities. Considering NGK makes

their own wideband sensors, it is a surprise this unit

ships with a Bosch sensor. |

Dynojet

The Dynojet unit was hard to set up, and the included

logging software was very limited. The Dynojet exhibited

the slowest response time tested. |

FAST

The FAST unit had internal datalogging, but no separate

logging analysis software. This perhaps makes it less

useful for complex tuning, but is really "to the

point" for those wanting no-frills wideband tuning.

Setting up the analog outputs was somewhat difficult.

Display is nice and intuitive. More

on the FAST unit. |

FJO

The FJO unit had tricky wiring for the sensor, the controller,

and the analog outputs. It was also difficult to setup

the analog outputs with the included configuration software.

The included logging software was counterintuitive. |

Innovate

The Innovate unit was accurate, exhibited the fastest

response time, and included very good analysis software.

Innovate claims to be the only truly digital unit, and

the high accuracy and low latency seem to support their

claims. Setup and wiring was complex and somewhat confusing.

|

PLX

The PLX M300 does not include logging software, and exhibited

accuracy at +/1 AFR (the worst tested). Note that PLX

has commented below, and believes we did not wire their

unit properly in that we used a common ground for all

units. |

Zeitronix

The Zeitronix exhibited accuracy of +/- .54 AFR, and gradual

lean drift under some conditions. The included logging

software was relatively difficult and lacked features.

Note that Zeitronix indicated we may have reviewed an

outdated unit (see comments below.) |

|

|

The only regret we have is that we couldn't effectively simulate

long-term sensor "aging." Aging is mostly due to

oxidation of the sensors internals and fouling of its ceramic

elements. Operating conditions and fuel type are big factors

in the aging process. Exposure to lead in race gas, metallic

elements in octane booster additives, oil or carbon fouling

and really high operating temperatures contribute to rapid

aging, and a resulting loss of sensor accurancy. Because of

aging it is important to have an air fuel ratio meter that

can be calibrated. The common type of calibration is called

a free air calibration. This is when the meter compares the

output of the sensor to what it should be when exposed to

a know oxygen content gas, air. If an air fuel ratio meter

is lacking the ability to calibrate, the sensor should be

replace at regular intervals. The trouble is when should the

sensor be replaced? It takes some experience to know when

this is appropriate.

We did try to emulate this idea using a variety of old and

damaged sensors we had laying around. With one of these sensors,

the Innovate XD-16 would show an error code indicating that

the sensor was bad. However, when we connected the same damaged

sensor to any of the analog gauges they read as much as 3

AFR off. Again, the obvious question is: If your gauge can't

tell you when a sensor is bad, how could you ever trust it?

Optimizing Wideband Sensor Usage

Other things to keep in mind to ensure proper sensor function

and longevity are exhaust back pressure, rich mixtures, and

under/over heating.

A

high exhaust backpressure forces more exhaust into the sensors

pump cell which can cause an air fuel ratio meter to read

richer than what the engines really running. Turbo engines

run a relatively high amount of backpressure in the exhaust

manifold before the turbine, making them a poor place to locate

the sensor. A

high exhaust backpressure forces more exhaust into the sensors

pump cell which can cause an air fuel ratio meter to read

richer than what the engines really running. Turbo engines

run a relatively high amount of backpressure in the exhaust

manifold before the turbine, making them a poor place to locate

the sensor.

Missfires due to a malfunctioning or underpowered ignition

or an extremely rich mixture can cause false lean readings

because unburned liquid fuel in droplets block the small hole

leading to the sensors pump cell.

A wideband sensor should not be placed in the exhaust stream

and left unheated. The hole to the pump cell can quickly become

clogged and contaminated by exhaust byproducts, especially

during a start cycle from a cold engine. The sensor can also

be damaged by exposing it to temperatures above 700 degrees

C, like those typically before the turbine in turbo engines.

You never want to place a sensor there anyway due to the aforementioned

issues with sensor accuracy and backpressure. Lastly you don't

want to place the sensor so far away from the engine that

its 10 watt internal heater cannot keep the sensor hot enough.

|

|

|

Posted by ZephyrZ7, 06/27/07 06:02pm:

sweet! Glad I've got an Innovate!

Posted by 10SecS4, 06/28/07 12:54am:

What is an NTK AFX Meter? I think you guys mean NGK! I have this wideband and am very happy with it. In fact, it reads pretty darn close to my narrowbands at WOT. Oh and I paid $209 shipped for it after Summit price matched an "old" price from back in February.

One thing you guys didn't test is RELIABILITY of these wideband 02 sensor systems. I have several friends who had nothing but problems with the AEM UEGO gauges crapping out.

Posted by chopsuey, 06/29/07 09:49am:

I have the AEM unit and I love it. I've used it on multiple cars to tune and they are pretty easy to setup once you get used to it. The software is pretty hard to use but you just got to fiddle with it. I would highly reccomend the AEM unit to anyone looking for a wideband setup. Very accurate system with a very good price.

Posted by Teratum, 06/29/07 03:16pm:

I am skeptical about the accuracy of the accuracy test iamong these sensors. I think the accuravy data will be credible if all the sensors read the calibrated gas from the same test chamber at the same time and then AFR readings for each one is compared to the supposed reading of the calibrated gas. The picture 1 in the article shows each sensor is held in free-air at the end of the gas cylinder. I'm not sure if I can believe the test result to be accuarate for all these sensors.

Posted by Megascott, 06/30/07 09:42am:

I'm not sure of the value of the logging software on most of these meters, maybe you need it when running a carb, but for EFI most, if not all, of the aftermarket EFI controllers support Datalogging of the analog signal. Certainly Megasquirt EFI does, and I've compared the digital signal of my innovate LC-1 to what the Megasquirt reads and it's spot on.

Posted by rcamp, 07/02/07 07:44pm:

Quote: In fact, it reads pretty darn close to my narrowbands at WOT.

I love it, using a narrowband sensor to validate the accuracy of a wideband. Why even bother with the wideband if a narrowband is acceptable.

Posted by chopsuey, 07/03/07 08:33am:

"In fact, it reads pretty darn close to my narrowbands at WOT." I would never take my car to a tuner that uses a narrowband to tune.

Posted by 10SecS4, 07/03/07 07:31pm:

The point is that if neither were accurate, I somehow doubt they'd both be inaccurate to the point where they read exactly the same.

Who cares about accuracy of A/Fs anyway? I'm going to tune for max. power, so it doesn't matter if the engine makes max. power at an indicated 13:1 or 14:1. All that matters is that the "magic number" is consistent.

Posted by admin, 07/04/07 07:02pm:

Some response from PLX:

http://www.plxdevices.com/forum/viewtopic.php?t=1312

Posted by Helmantel, 07/05/07 08:23am:

I work in an engine lab and work with emission measurements and engine testing on a daily basis. I must agree with Teratum. The method of holding the sensor in front of a bottle of calibration gas is not a good one. There is a significant risk that atmospheric air dilutes the gas.

Posted by mikekojima, 07/06/07 03:01pm:

Our testing suggested that calibrated gas velocity was sufficient to completely fill the sensorís measurement chamber, and exclude any free air. This appeared to be confirmed by the fact that Westecís expensive ECM LambdaPro matched the exact lambda values of the calibrated gasses.

We used 2 bottles of 1% tolerance calibrated lab gas from Scott Specialty Gasses. These were formulated to SAE standards for .8 lambda and .895 lambda (11.76 AFR and 13.15 AFR respectively). As an added data point, we used Westecís LambdaPro during every round of testing (and it always matched the SAE gasses).

Thereís always room for improvement, but we believe that our methodology was a good and practical balance, and more precise than any tests weíve seen in the past. Having said that, perhaps we should put together another comparison. As stated in the article, the question of accuracy over the life of the sensor is still open. I donít know if Iím the guy for the next one, but if all of the manufacturerís agree to share the cost, Iím sure we can come up with an agreeable plan.

Posted by 4iFordGeek, 07/06/07 04:36pm:

I have to disagree with Helmantel and Teratum. I routinely use a butane lighter to saturate the sensor on my PLX unit. Even with the relatively low gas pressure, it is easy to bottom out the sensor to a reasonable value.

I actually do this because there is no way to adjust the unit for non standard partial pressure. So, when I tune at home I start with a new sensor and get a base value from the butane. Then when I am at the course I can use the butane to calculate a fudge factor for the change in partial pressure. I then tune back to the fudged number and generally get very repeatable results. I really do not understand the commotion at the PLX site. I would have thought that they have used lighters and stuff like me. Once you have used a butane lighter to send the sensor to a value (which it basically holds until you blow on the sensor to clear its test chamber) I don't think you would have any doubt about gas roaring out of a big pressurized tank.

Ambient air just doesn't seem like an issue. Neither does puff to puff consistancy from the tanks. This is very similiar to how a 5 gas analyzer is calibrated. Two things that might be an issue are cooling and gas pressure. Depending on the gas there might be a venturi effect right by the valve. If I understand the Bosch specification correctly the sensor only gives accurate readings at a specific temperature. So if there is cooling from the gas the heater control circuit will have to overcome it. However that seems like an even more accurate scenario. On big bore engines it is often a problem to keep sensors hot enough for the catalytic action used for the measurements to occur. Gas pressure is another matter. The Bosch specification shows some additional gas pressure related errors. If the sensor was stuffed into the end of the valve too tightly the readings may have been less accurate than with the lower pressure flow of a high performance exhaust system. But since the same sensor is used for all the instruments I would expect similiar results using the same techniques.

I suppose part of the reason I am no worked up is that I truly am a geek. I am not surprised to see my unit rated as a .5 AFR unit because that is very reasonable based on Bosch's documentation. In the datasheet I have (sorry, I could not find an online version to link to) the LSU 4.2 sensor is rated to be +/- .01 lambda with .8 lambda gas when the sensor is brand new. That means that brand new my readings could be off by about .15 AFR in either direction and still be working perfectly. After 500h Bosch only promises +/- .02 lambda. So in short order being off by .3 AFR in either direction is normal. By 2000h they only promise .04 lambda. All this is under optimum conditions. When you consider that the calibration resistor from Bosch is from standard partial pressure and temperature (that is why I do the butane test at different locations) being a .5 AFR instrument with an artificially aged sensor seems perfectly reasonable to me.

Posted by mikekojima, 07/15/07 10:00pm:

Some question have come up to me about the test methdology, some of which was edited out for clarity.

Here is here is the main part that was editied out.

Test Methodology

On the dyno we hooked all of the control unitís power and ground wires to the battery and the battery to the dynoís 150 amp power supply. The battery would act like a filter to help smooth and rectify the power to the control boxes and act as a very solid ground to avoid ground loop voltage differentials between the boxes. During the dyno testing, we logged data from all of the units. This gave us a chance to configure each unitís analog outputs for data logging in the same way a customer would, and to compare response time (latency) and accuracy under various loads, sweeps, and conditions. We also verified that the logged data matched the values displayed on the various gauges and displays.

Now I am not an electronics expert nor am I an EE but I think I could call myself an educated consumer and I ran the test using the equipment as a consumer might.

It has been brought to my attention that there were several places that errors could have skewed the test results.

The first being differenentials in ground loops. Although I tried to eliminate this by placing a battery between the power supply and the units themselfs, I have been told by several manufactures that this is not enough and that all units should have individual grounds and power with the same resistance in every units ground. I am reporting this complaint as it was brought to my attention by several companies who make these units.

The second is that by using units analog outputs, the accuracy is only going to be as good as the interpolation between the points is going to be as well as an A to D conversion error.

Now I am not smart enough in the field of electronic deisgn to argue for or against these points but more than one manufacture mentioned this to me and to be fair I must report this.

I hope this clarifies some of these results and allows the more educated readers to more accurately draw conclusions to how good this test is.

Mike

Posted by admin, 07/23/07 02:14pm:

I am writing in response to the article "Air-Fuel Meter Shootout!" by Mike Kojima, published on the Fordmuscle.com web site.

First of all, I want to express to you that Fordmuscle.com and PLX Devices both share common objectives in educating our customers, enthusiasts, and readers in order for them to become well informed consumers. PLX Devices is always in full support of any product performance comparison published by Fordmuscle.com as well as other publications.

However, PLX Devices has reviewed your article and strongly believe that your test methodology and test setup is unsatisfactory according to the standards of the engineering and scientific community. We believe that this lead to the misrepresentation of our M-300 as well as other products reviewed. With reference to picture 1 in your article, holding each sensor against the gas canister at an angle like the picture shown is highly susceptible to external variables which influence the accuracy of the measured results. With reference to picture 4, the power connections which share a common power and ground with 7 other products, without proper filtering can introduce coupling and unwanted noise created from the switching behavior of the 7 other oxygen sensor heater circuits. This can introduce errors in the analog output interpretation of each product. Throughout all the tests that are being conducted in the article, there was no mention on the number of test iterations for each sensor, its average value, range, and standard deviation for both results obtained from the digital display as well as the captured analog output signal.

To properly perform a comparison test, all the sensors must measure the same gas, at the same time in a sealed enclosure, with equivalent temperature and pressure. The gas must then be allowed to settle and equalize in the enclosure before taking any measurements. The experiment must then be repeated with the sensor positions inside the enclosure randomized as well the sensor controller combination to obtain several data points. To properly connect power to each controller, a low pass filter should be introduced to isolate the effects of the switching behavior introduced from the 7 other products tested. With the M-300, we've included noise filtering capacitors (0.1uF) which is recommended to be connected near the input of your data logger. This helps filter high frequency noise coupled from switching electronics in such a setup like this. The average value, range, and standard deviation must be collected to derive accurate and true results for both the digital display as well as the captured analog output signal.

PLX Devices is looking forward to seeing the tests re-conducted and re-published to acceptable industry standard as described above. In PLX's view, accuracy is the most important criteria for doing this test. We believe that testing conducted in a controlled environment will yield very different results from the one published in your story.

Sincerely,

Paul Lowchareonkul

President and CEO

PLX Devices Inc.

Posted by marc99, 07/25/07 10:09am:

rcamp is pretty much correct -

In the range that most tuners work in, a narrowband works well enough - as long as we keep in mind that whatever the supposed "AFR" is - it's ONLY a rough clue of the real AFR and even if it was the "correct" AFR reading - you really don't know exactly what the engine wants - you MUST tweak fuel up and down to get Best Power to do good tuning.

Marc Salvisberg

www.factorypro.com

415 491 5920

Posted by tdw6974, 09/23/07 04:35am:

looks like none of units tested are good????

Posted by lx347cid, 11/18/07 03:41pm:

I dont see the Zietronic comment like you mention?

|

|

|

|

|

|

|