|

by FordMuscle Staff

The valve covers on a motor are

like a family crest above a castle. They signify not only

the caliber of motor on which they are bolted to, but the

pride the owner, or engine builder, has taken in building

that engine. It's for that reason that serious enthusiasts

eventually invest in a set of proper valve covers to replace

their stock steel or cheap catalog ornaments. Valve covers

come in a variety of materials - from stamped steel or aluminum,

to die cast aluminum, and even polymer composite. However,

it is the fabricated (welded) aluminum which are the cream

of the crop. Stamped and composite covers tend to warp with

repeated removal and installation. In general, stamped covers

are not good for the enthusiast who is constantly getting

under his covers to adjust rockers. For this, only a quality

pair of heli-arc welded billet aluminum covers will hold up

for ever. Billet aluminum covers may cost several hundred

dollars, but they will indeed be the last valve covers you

ever buy. It's important therefore, that if you do spend some

of your tax return on a set that you set them up correctly.

We're putting on a pair of Moroso's new fabricated billet

covers for the 429-460 big block Ford. These are professional-grade

covers and as such, they don't come pre-drilled for crank

case ventilation. With covers like these you need to decide

what type of PCV, breathers, or crankcase evacuation pump

you plan to run and then modify accordingly. Follow along

as we show you how to install a set of simple breathers without

messing up your pricey jewels.

These are not inexpensive valve covers, but you get what

you pay for in this case. Quality stuff. At this level,

you are expected to know how to add breathers or an evacuation

fitting.

These are not inexpensive valve covers, but you get what

you pay for in this case. Quality stuff. At this level,

you are expected to know how to add breathers or an evacuation

fitting. |

|

Since we weren't running a crankcase evacuation setup,

we needed to install some breathers and a place to add

oil of course. These universal breather stands from Comp

Cams bolt-on and allow use of clamp-on breathers.

Since we weren't running a crankcase evacuation setup,

we needed to install some breathers and a place to add

oil of course. These universal breather stands from Comp

Cams bolt-on and allow use of clamp-on breathers. |

| |

|

|

I learned my lesson, whether it's an air cleaner element

or a breather like this one, just buy K&N when you

need a good filter. See

"Stupid, Stupid Stupid" in the FMWire

I learned my lesson, whether it's an air cleaner element

or a breather like this one, just buy K&N when you

need a good filter. See

"Stupid, Stupid Stupid" in the FMWire |

|

Valve cover gaskets come in a variety of materials and

thickness'. We went with these steel-core cork and rubber

gaskets from Ford Motorsport.

Valve cover gaskets come in a variety of materials and

thickness'. We went with these steel-core cork and rubber

gaskets from Ford Motorsport. |

| |

|

|

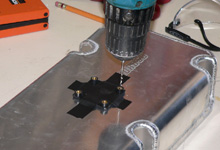

We sized up a good spot on the valve cover to pop a 1-1/4"

hole.

We sized up a good spot on the valve cover to pop a 1-1/4"

hole.

|

|

With a dry erase marker and an aluminum level, we marked

off the centerline.

With a dry erase marker and an aluminum level, we marked

off the centerline. |

| |

|

|

It's important to be very cautious around these aluminum

valve covers, they can gouge easily with hand tools. A

good quality hole saw and patience will do the trick.

Got a drill press? Even better.

It's important to be very cautious around these aluminum

valve covers, they can gouge easily with hand tools. A

good quality hole saw and patience will do the trick.

Got a drill press? Even better. |

|

Here, we de-burr with a Dremel. This is important for

two reasons. First, to prevent any flesh wounds and second

to ensure a good seal once the breather stands are added.

Here, we de-burr with a Dremel. This is important for

two reasons. First, to prevent any flesh wounds and second

to ensure a good seal once the breather stands are added. |

| |

|

|

With the breather stand base taped into place, we marked

the locations for the four holes which would secure the

assembly to the valve cover. Next, it was removed and

the proper size holes were drilled.

With the breather stand base taped into place, we marked

the locations for the four holes which would secure the

assembly to the valve cover. Next, it was removed and

the proper size holes were drilled. |

|

The breather stand base is taped to the bottom and ready

to receive the set screws.

The breather stand base is taped to the bottom and ready

to receive the set screws. |

| |

|

|

With the valve cover flipped right-side up, the gasket

is added to the base. Notice there is a baffle on the

base.

With the valve cover flipped right-side up, the gasket

is added to the base. Notice there is a baffle on the

base. |

|

Since we were performing this on both valve covers, one

of the stands had its baffle removed to allow motor oil

to be added easily.

Since we were performing this on both valve covers, one

of the stands had its baffle removed to allow motor oil

to be added easily. |

| |

|

|

This is the stand for which the baffle remained. Therefore,

with the base and the stand, there are a total of two

baffles on this valve cover.

This is the stand for which the baffle remained. Therefore,

with the base and the stand, there are a total of two

baffles on this valve cover. |

|

The black screw came with the kit but caused some interference

with the rockers.

The black screw came with the kit but caused some interference

with the rockers. |

| |

|

|

The silver screws from Ace Hardware fit better. Click

photo to enlarge.

The silver screws from Ace Hardware fit better. Click

photo to enlarge. |

|

This was a shot before we switched to the shorter screws.

Anyway, all four were tightened so as not to extrude the

gasket.

This was a shot before we switched to the shorter screws.

Anyway, all four were tightened so as not to extrude the

gasket. |

| |

|

|

The special oil solution from K&N was added to each

breather.

The special oil solution from K&N was added to each

breather. |

|

The finished product looks great. However, just like home

improvement, remodel one area and suddenly there's more

upgrading to be done.

The finished product looks great. However, just like home

improvement, remodel one area and suddenly there's more

upgrading to be done. |

|

Posted by myfast5oh, 03/31/07 04:20am:

The welded covers look horrible.

I believe there are much nicer

covers on the market .

Although the welder is very

talented and has a neat weld.

Posted by GrandSAC, 04/10/07 12:20pm:

Great article and solution. This will solve my issues

with oil leaks from the O-ring type that I am currently

using on my SBF 347.

Posted by karguy1, 04/10/07 10:51pm:

Is it cool to run without a PCV on a street car?

Posted by papacito, 04/18/07 10:49pm:

If I bought all the parts and kits hyped I'd have $100K in a $10K car.

Posted by walkertejas, 05/03/07 05:14pm:

Kevko racing sells IMCA style valve covers that

work like they should. Zinc plated stamped for

like $39 bucks. I'm not into "pretty".

What do you when one of the inserts spins or breaks

with the valve cover on?

Can you tell I don't like this add on breather deal?

Simple solution if you have aluminum covers

is get a welder to mig/tig on some 1.25 aluminum

tubing around the rear of the covers towards the top.

Add some breathers and go...

Posted by 68Coop, 06/05/07 12:59pm:

Is it cool to run without a PCV on a street car?

From what I've heard it will eventually mess up the engine, so I wouldn't if I were you.

Posted by JosephLynch, 08/24/10 06:53pm:

During the rebuilt of my motor I had opted for AFR heads with rollers and the stock Valve covers wouldn’t fit. So I opted for the trick flow covers to match my intake. Well they come in and I get that nice Christmas buzz off getting a new toy. Open the box and loose my mind!!!!!!! I am thinking they sent me incomplete covers! There is not ant place to run my Blow back or a place to put oil in the dang motor. After a bunch of choice words for Trick Flow and the distributer I pick up the phone completely ready to give the sales department an ear full. Luckily for me my Father in-law (we are close friends) had stopped by as I dialed so I hung up to show him the snafu. Of course he is a mechanic and has spent lots-n lots of money in his hay day at the track. So he starts laughing like a mad man and of course I naturally start laughing as well. Here I am thinking he is laughing at my poor luck come to find out he was laughing at me. He then kindly informs me that it is standard practice to install your own venting and fill points on aftermarket covers.

So that’s my story laugh at me or with me I can take it.

|

|

|

|

| |

|

In This Article...

Buy a pair of valve covers without accommodations

for breathers and you'll have to pop your own

holes. Whether they are stamped steel or fabricated

aluminum, it's a great opportunity to go "grommet-less."

|

|

|

|

|

|

|