|

by Jon Mikelonis

Introduction

Stop calling your project a "Budget-Build" and quit

justifying your parts

gathering methods as "Resourceful". Stand up and

be counted, you're just cheap. That's right, cheap. The authorities

have been monitoring you and you've been caught scrounging

wrecking yards, slipping hardware into your tool bag, bumming

needle-nose pliers from fellow archaeologists, and purchasing

used junk that can be better had at the national chain store.

Now that you've been blindsided with the cold hard truth,

it's time you're held responsible for the cheap habits you've

been exhibiting in order to acquire those precious parts.

If you're wallowing in the revelation you just received, then

buck up bud because "cheap" is just a state-of-mind

and the dictionary has provided you with a way to confidently

brush off any future personal attacks. Attacks that target

your stingy nature in hands-on Ford restoration and modification.

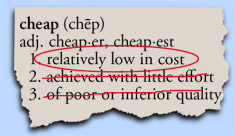

According

to the adjacent graphic, cheap can be defined three different

ways. Working from the bottom to the top, entry number three

doesn't apply to you because while you are price-conscious,

knowingly using "poor quality" or "inferior

parts" on your project car defeats the purpose of your

time and effort spent in this hobby. The next rung on the

ladder defines cheap as; According

to the adjacent graphic, cheap can be defined three different

ways. Working from the bottom to the top, entry number three

doesn't apply to you because while you are price-conscious,

knowingly using "poor quality" or "inferior

parts" on your project car defeats the purpose of your

time and effort spent in this hobby. The next rung on the

ladder defines cheap as;

"achieved with little effort". Spending half your

Saturday driving from

wrecking yard to wrecking yard in order to find the iron hulk

that possesses the brake rotor you need, which still requires

removal, does not exemplify "little effort". On

the other hand, if that brake rotor you need to pull is in

good condition and costs only $19.99, while the national retailer

is charging $149.00 for a new unit, then your effort just

met the first definition of cheap. So, if doing what it takes

to get parts that are "relatively low in cost" means

you've still got enough cash left over to take your wife or

girlfriend out for a nice dinner, then being called cheap

is something both you and the rest of us can live with.

"Cheap" Fixes

This past November marked the one-year mark since we picked

up Project MX in Fresno, CA. Since then we've made the 1972

Montego roadworthy and after this article we will have achieved

nearly all the objectives we set out to accomplish. Following

is a run down of our most recent progress on Project MX. To

accomplish these "budget-minded" fixes we practiced

much "resourcefulness". Forget about it... we were

just "cheap".

Collapsed upper control arm bushings were making this

car unsafe. We chose not to drive the Montego until the

bushings were replaced with urethane. As usual, these

type of projects uncover more worn components.

Collapsed upper control arm bushings were making this

car unsafe. We chose not to drive the Montego until the

bushings were replaced with urethane. As usual, these

type of projects uncover more worn components.

|

|

Yes, that's a very original looking shock down there,

"Auto-Flex". At these moments it's tempting

to remove the entire front clip and embark on a complete

front-end restoration. We held back due to time and money

of course.

Yes, that's a very original looking shock down there,

"Auto-Flex". At these moments it's tempting

to remove the entire front clip and embark on a complete

front-end restoration. We held back due to time and money

of course. |

| |

|

|

|

Installing new ball joints and bushings into filthy

control arms is disheartening. We dropped both sets

of arms off at the machine shop for a wash.

Installing new ball joints and bushings into filthy

control arms is disheartening. We dropped both sets

of arms off at the machine shop for a wash.

|

|

Both rotors were worn beyond their limit. We found another

72 Montego at the local Pick N' Pull. Sure, www.partsamercia.com

and the local chain had them available but we couldn't

accept the price tag.

Both rotors were worn beyond their limit. We found another

72 Montego at the local Pick N' Pull. Sure, www.partsamercia.com

and the local chain had them available but we couldn't

accept the price tag. |

| |

|

|

Do you ever go to the wrecking yard actually expecting

to find what your are looking for? Why bring the tools

you need? We made a "cheap" breaker bar out

of a stock jack and braced the tire with a Chevy Van center

console.

Do you ever go to the wrecking yard actually expecting

to find what your are looking for? Why bring the tools

you need? We made a "cheap" breaker bar out

of a stock jack and braced the tire with a Chevy Van center

console.

|

|

These rotors were within limit so we had them turned at

our favorite independent general repair shop, Mike's

Auto Perfection in Reno, NV. When you find a local

shop that treats you right, do them a favor and keep going

back for jobs you can't do. We replaced the races, bearings,

and seals ourselves.

These rotors were within limit so we had them turned at

our favorite independent general repair shop, Mike's

Auto Perfection in Reno, NV. When you find a local

shop that treats you right, do them a favor and keep going

back for jobs you can't do. We replaced the races, bearings,

and seals ourselves. |

| |

|

|

|

Next, we attacked the upper ball joints with a high-speed

grinder by knocking off the large rivet heads.

Next, we attacked the upper ball joints with a high-speed

grinder by knocking off the large rivet heads.

|

|

Standard replacement ball joints cost us a trip to the

chain store, that's OK because we got out of there for

next to nothing.

Standard replacement ball joints cost us a trip to the

chain store, that's OK because we got out of there for

next to nothing. |

|