|

Exhaust

Port Analysis

Airflow through

a cylinder head is more sensitive to shape than size.

Sudden changes in direction, volume, or shape do not

encourage good flow. For these reasons the factory 429

casting did not fair well in our exhaust flow test.

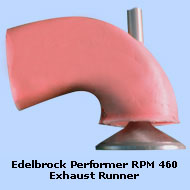

To demonstrate the difference in exhaust runner shape

and contour between the Edelbrock head and the factory

429 head we took silicone molds of both heads.

A

mold of the D2VE-AA exhaust runner clearly shows why

exhaust flow numbers are poor. Constriction due to the

massive valve guide boss hampers flow along the top

of the runner. Protrusion of the pushrod passage pinches

the runner. Perhaps most crucial is the steep angle

of the short turn radius. The sharp turn disrupts the

flow of exhaust gasses transitioning from the bowl into

to the runner. Gas flow becomes turbulent in this area

which further hinders flow. The overall volume of the

runner is insufficient to support the amount of air

the intake runner is bringing in. Exhaust to Intake

flow ratio drops to 59% in the mid-lift range. A

mold of the D2VE-AA exhaust runner clearly shows why

exhaust flow numbers are poor. Constriction due to the

massive valve guide boss hampers flow along the top

of the runner. Protrusion of the pushrod passage pinches

the runner. Perhaps most crucial is the steep angle

of the short turn radius. The sharp turn disrupts the

flow of exhaust gasses transitioning from the bowl into

to the runner. Gas flow becomes turbulent in this area

which further hinders flow. The overall volume of the

runner is insufficient to support the amount of air

the intake runner is bringing in. Exhaust to Intake

flow ratio drops to 59% in the mid-lift range.

It

doesn't require much more than basic physics to see

why the Edelbrock exhaust port flows over 20% greater

than stock. It is important to note that this is not

achieved by simply making the runner larger. The short

turn radius is laid down at a less severe angle. The

valve guide boss is cut flush with the roof of the bowl

area. The overall "macaroni" shape of this

exhaust runner promote smooth laminar air flow. Perhaps

most impressive is that the results are achieved without

modifying the exhaust port location. It

doesn't require much more than basic physics to see

why the Edelbrock exhaust port flows over 20% greater

than stock. It is important to note that this is not

achieved by simply making the runner larger. The short

turn radius is laid down at a less severe angle. The

valve guide boss is cut flush with the roof of the bowl

area. The overall "macaroni" shape of this

exhaust runner promote smooth laminar air flow. Perhaps

most impressive is that the results are achieved without

modifying the exhaust port location.

Design Strategy Q & A

Edelbrock Engineer, Jim Dralle, answers our questions

regarding the development of the Performer RPM 460 Cylinder

Head.

Q: FordMuscle flow tested

the Performer RPM 460 Cylinder Head against a standard

factory iron head (D2VE-AA). We were surprised to find

that the factory 429 head flowed quite well on the intake

side. The Edelbrock head flowed as advertised with excellent

improvements over the factory head on the exhaust side.

From this data we concluded that a great deal of the

development of the Performer RPM 460 head was spent

on improving the exhaust runner to achieve a better

balance with the already well-designed factory intake

runner. Would you say this conclusion is accurate?

A:

I would say this conclusion is accurate. I have always

found it funny that the highest performance stage in

the Ford performance handbook for 429 Fords is to remove

the Cobra-Jet heads in favor of ported Standard heads

modified to fit with a CJ intake manifold. The layout

of the 460 Ford engine favors the intake port design.

The exhaust port with the exit flange position given

by the stock design made it very challenging to design

an exhaust port that performs well. Designing ports

that can be consistently manufactured is also a big

part of the development process.

Q: What

was done to the Performer RPM 460 Head to improve the

exhaust flow over the factory design?

A: One of our best

port designers has said "it is not important where

you

remove material in the port, it is were you leave the

material that is most

important". The short turn area is the most critical.

If it is too-high

the flow will separate. If it is too-low, even if it

may flow well, the port

will not be consistently manufacturable. If I was going

to detail only one

area of the ports it would be the exhaust short turn

area. Careful

detailing of this area will yield more power potential.

Q: Did the development

of the Performer RPM 460 Cylinder Head require any compromise?

A:

The most difficult application for which to design a

cylinder head is an

application that is required to mate with stock intake

manifolds and exhaust headers. The fact that the 460

Ford engine was designed with two different intake port

configurations (standard and Cobra-Jet) definitely created

some issues that had to be decided at the beginning

of the design process. In general the head is designed

specifically for the largest customer base but material

is placed in the the head at the right locations to

allow easy modifications that will suit other potential

users. Combustion chamber

size was also another issue that presented itself early

in the design process. Some customers wanted an CJ size

chamber and some desired a larger volume chamber that

would produce lower compression ratios with stock configuration

pistons. In this case we decided to design and offer

two different combustion chambers.

Conclusion

Whether you are building a 460 or not, when having a

pair of your own heads power tuned or when shopping

for aftermarket heads, keep in mind that the areas of

a runner that are the most difficult to see and reach

offer the greatest performance gains. In the case of

a cylinder head modifier, this is where they will spend

the most time massaging the head. In the case of the

manufacturer, this is most likely where the greatest

Research and Development work will be performed. Sure,

when we received Edelbrock's Performer RPM 460 heads

for our recent BBF build we knew we were making a leap

towards better performance. However, it wasn't until

we compared the head by flow testing and taking molds

of the runners that we realized our decision was a sound

one. Watch for FordMuscle's continuation of the article

Streetwise 460 for real world testing of the Edelbrock

Performer RPM 460 cylinder head.

|