Gromm

Racing Heads flowed the head on a Superflow 600 flowbench, the industry

standard.

The head was tested at a standard pressure of 28-in. of H20. To simulate

actual transitions, the intake side was fitted with a clay lip, however

no extension was used on the exhaust port.

A 4.030" cylinder was attached to the combustion chamber to simulate

the bore. The end chamber was tested on each head.

Both the intake and exhaust side were flowed in .100" lift increments,

to at least .600", or until max flow was reached. |

|

TAKE

A DEEP BREATH! TAKE

A DEEP BREATH!

The

intake side of the new ROUSH 200 head shows a marked improvement

over its older brother, the World Sr.

Gromm pointed out to us that it appears World has made some changes

to the short side radius on the new heads -specifically the radius

is shorter and steeper. This typically will increase high-lift flow,

but could hurt low end flow. However World has balanced this with

other modifications to the intake runner.

The resulted is a 5-7% improvement in mid-lift flow compared to

the World. Sr. head.

Gromm did indicate that the valve guide bosses still have too much

material around them. Removing the excess material and reshaping

the guide-boss would show some reduce turbulence and improve flow.

Furthermore notice how the new head never trails off in flow, even

at 0.700" lift, where the Sr. is starting to decline.

|

|

It

is tempting to look at these flow numbers and compare them directly

to those of the leading aftermarket aluminum heads. However this

is not a fair comparison considering ALL aluminum heads have some

degree of CNC port work as part of the manufacturing process. This

is part of what contributed to the higher cost of aluminum heads. It

is tempting to look at these flow numbers and compare them directly

to those of the leading aftermarket aluminum heads. However this

is not a fair comparison considering ALL aluminum heads have some

degree of CNC port work as part of the manufacturing process. This

is part of what contributed to the higher cost of aluminum heads.

On

the other hand, cast iron heads have very rough surface finishes

and some casting ridges to contend with.

Gromm indicated that a simple cleanup job with a Dremel and sanding

rolls would yield 8-10% increase in flow over the out-of-the-box

numbers. Now you've got some numbers to compare against TFS, AFR

and the like -and you are still saving hundreds of dollars.

|

EXHAUSTED! EXHAUSTED!

The exhaust side of the World/ROUSH 200 heads is where we did a major

double-take. The port simply stopped flowing beyond 137 cfm at 0.400"

valve lift.

Initially we thought there was a problem with the flow bench, so Bob

Gromm checked to ensure everything was operating correctly and flowed

the exhaust port again. No change.

As the chart shows, the head simply shuts down at actually 0.300".

At 0.500" we calculated the percent exhaust to intake flow is

a wheezing 59.75% Ideally an exhaust port should flow 70-80% of the

intake flow.

|

|

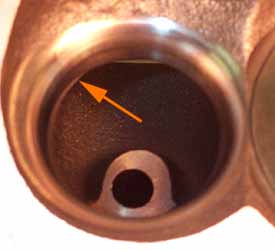

| The

poor exhaust flow is most likely due to this serious misalignment

between the valve seat and the exhaust bowl. We noticed this

on all the ports, and two sets of ROUSH 200 heads -indicating

a problem with the mold for these heads. |

Conclusion

Needless to say there is a major problem with the exhaust side of

the new ROUSH 200 head. Interestingly, one of the first things we

noticed, days before we had the heads flow tested, was a 1/16"

ridge where the exhaust valve seat meets the bowl. The ridge extends

about 180° around the short side radius of the bowl.

Our initial thoughts were that perhaps this was a problem with just

one port. However Gromm happened to have a couple sets of bare ROUSH

200 heads at his shop, and they too displayed the same problem.

Gromm suspects that the problem is due to "core shift",

a problem where the original mold for the head shifts off center,

subsequently affecting all the heads cast from that mold. The valve

seat is pressed in to the original design specifications, resulting

in a mismatch between the seat and head. This little ridge, especially

on the short side radius, can disrupt flow to the point that the turbulent

gas effectively blocks the port.

We reported our results to World Castings, and they confirmed that

they were working on fixing the core shift problem. We recommend that

you hold off on these heads until World has the problem resolved.

We do think that this is a head which shows tremendous potential for

the budget minded racer who is willing to put in a little effort.

As we mentioned, a few hours behind a Dremel tool or die-grinder and

you'll have a head in the 250 cfm range, but more importantly it will

maintain that level beyond 0.600" lift if you plan to run a monster

cam. |

|

| The

budget Manley "Street-Flo" valve on the right is found

in just about all aftermarket Ford heads. Buying the heads bare

and stepping up to the "Race Master" valve (left)

improves flow and reduces turbulence. |

Valves

and things

One of the many interesting facts Gromm pointed out to us during our

visit to his shop was the importance of valves and their effect on

flow. We've known for some time, and Gromm confirmed, that ALL aftermarket

head manufacturers use budget valve train components to keep costs

down. Typically the springs are setup for a stock or mild flat-tappet

camshaft, and as we saw with the Edelbrock

heads, inferior shims may be used.

World has taken a step in the right direction by offering the ROUSH

200 with three levels of springs -depending on the type of cam (roller

versus flat tappet) and the amount of lift. (Check their website or

catalog for springs specifications.)

The other area companies notoriously cut costs is in the valves. The

most common valve used in the industry is the Manley Street Flo (right

one in our photo.) The valve boasts undercut stems and a swirl polish.

However Gromm pointed out that the angle of the valve head and the

thickness, or "margin", of the face has a huge effect on

flow. The thinner margin valves are typically installed by manufacturers

to avoid customer complaints of piston to valve problems. However

the thicker margin valve actually reduces turbulence and results in

the gasses getting past the valve faster - due to better convergent/divergent

gas flow, a physical process whereby gasses (and liquids) form into

two conical shapes, like sand in an hourglass, as the pass through

the valve. The thinnner valve margin results in disruption and turbulence

of the gas, breaking up the conical flow.

Gromm installed the Manley Race Master valve (left) in one of the

exhaust ports and re-flowed our head. There was an immediate gain

of as much as 5 cfm at mid-lift. If you recall, in our Heavy

Breathing article, Total Engine Airflow also changed the intake

valve when they ported our World. Jr heads and saw a whopping 23cfm

gain at 0.200"!

Gromms recommendation -always buy heads bare and have a professional

shop set them up with better valves and springs to match your specific

cam. You spend a couple hundred dollars more, but end up with considerable

gains in power and reliability. |

|

| Like

many performance cylinder head shops, Gromm Racing Heads offers

a range of porting options. They have this Chevy head on display

which shows the four stages of port work. At about $285 the

Economy Pocket Porting would get the Roush 200 intake side above

270cfm range above half-inch lift. |

|

Sources:

World Castings

35330 Stanley

Sterling Heights, MI 48312

810-939-9628

Gromm Racing Heads

664 Stockton Ave. #J

San Jose, CA 95126

(408) 287-1301

|

|

|

|