|

From page 2

Pistons - Cast, Hypereutectic,

or Forged?

Most shops will

reach for OEM cast replacement pistons when

assemblying a stock bottom

end. There is nothing wrong with cast, unless you plan

to add a power

TRW/Sterling Pistons have

huge valve reliefs for 2.02" valves, but the

head volume is a gapping 8cc! |

adder or high compression. We

like to step up to hypereutectic simply because it offers

more strength than cast, and they experience less thermal

expansion than cast, meaning you can run a tighter piston

to wall clearance for better oil control and less scuffing.

Ultimately this translates to more power due to higher

cylinder pressure.

Many people scoff at cast or hypereutectic and immediatley

ask for forged aluminum pistons, without considering the

draw backs. While forged is undoubtedly the strongest

of the three pistons, that does not mean you will make

more power. First of all forged pistons are very heavy

- the Federal Mogul forged replacment piston for 5.0L

engines weighs 80 grams more than its cast or hyper counterpart.

The greater the reciprocating weight, the more power the

engine needs to turn over the crank. Secondly, as detailed

above, forged pistons have larger than stock valve reliefs.

This increases the head volume and lower compression ratio.

So unless you absoutely need a forged slug (forced induction,

high compresion, etc) you will save money and increase

power with a lighter hypereutectic piston.

Balancing Act

We called four reputable engine rebuilders and

machine shops in the Northern California area to inquire

about their beliefs on engine balancing. Suprisingly,

none of them included balancing as part of a standard

engine rebuild. They all charged between $175-$250 extra

to balance a rotating assembly, and in fact most of the

shops did not even do balancing in-house, they sent it

out to another shop if you opted for it.

Most rebuilders assume that because they are using OEM

replacement parts, that balancing will be within factory

tolerances. (Afterall, they tell you, Ford doesn't balance

each individual engine off its assembly line.) Take our

word, this is not a safe assumption -always pay the extra

$150-$200 to get an engine professionally balanced. If

it comes down to spending a couple hundred dollars on

balancing, or something questionable like torque plate

honing the cylinders, you will do more for horsepower

and life of the engine by balancing it.

We observed as much as a 30 gram difference between the

Silvolite replacment pistons and the stock pistons that

came out of our engine. According to Bay Area Balancing

guru Tom Benoit, this is more than enough to cause a noticiable

vibration, and accelerate bearing wear. Furthermore, machining

the crank and rods, installing a new replacement damper

and flywheel, and even a new clutch, are all things that

can drastically effect engine balance.

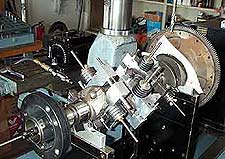

This is state of the art balancing

- a Hines HC500 micro-computer balancer. Before the rotating

assembly is spun, the piston and rods are

|

weighed

and equalize to the lightest one in the set. The weights

are recorded, and then bobweights matching the total rotating

weight of the piston, rod, rings, bearings, and even the

weight of the oil, are attached to the crank main journals.

Finally the harmonic balancer and flywheel (plus pressure

plate) are attached to the crank. The "replica"

rotating assembly is spun by the computer at several hundred

rpm, while it records the amount of out-of-balance and

the angle it is located at. The specialist then either

removes or adds weight by either drilling holes or welding

metal in the counter weights. Our balance shop (Bay Area

Balancing) shoots for less than 1 gram total out of balance

-in contrast, Ford specifications are abut 6 grams.

Completed Shortblock

Eventhough it took

a couple weeks, and two attempts at assemblying the motor,

in the end we got exactly what we wanted. The final short

block assembly had the correct H3101 hypereutectic pistons,

sitting at virtually zero-deck (measured at 0.003"

under). With 60cc aluminum heads we will have a pump-gas

friendly 9.55:1 compression ratio.

|

|

|

|

|

|

|

|

|

5.0L Short-Block

Specifications

|

| Bore |

4.020" |

| Stroke |

3.000" |

| Compression

Ratio |

9.55:1 |

| Piston

to Deck height |

0.003"

below |

| Piston

to wall clearance |

0.015" |

| Piston

top-ring end gap |

0.025" |

| Piston

2nd-ring end gap |

0.018" |

| Main

Bearing clearance |

0.0015" |

| Rod

Bearing clearance |

0.002" |

| Rod

side clearance |

0.018" |

| Main

Bearing Journals |

0.010"

undersize |

| Rod

Bearing Journals |

0.010"

oversize |

| Crank

endplay |

0.003" |

| |

| 5.0L Short Block Part

No's |

| Piston

4.020" |

Silvolite

H3101 |

| Rings |

Hastings

2M 5504 |

| Bearings |

Federal

Mogul |

| Block/Crank/Rods |

1989

5.0L |

| |

| 5.0L

Short Block Costs: |

| Standard

rebuild |

$795.00 |

| Machine

for Zero Deck |

$100 |

| Balancing |

$200 |

| Tax |

$101 |

| (core

charge) |

($400) |

| Total

Short Block |

$1196 |

|

| |

|

|