|  If

you've been following the progress of our 302 engine buildup and Project 11.99,

then know that we've been promising dyno numbers for the past couple months. We'd

been furiously trying to arrange some dyno time with a shop we has used in the

past. Unfortunately we never got a hold of them, so we ended up having to locate

another dyno. Well two days before this issue we finally found a shop at Sears

Point Raceway that had a chassis dyno. However let us tell you that we had some

apprehensions about getting the car tested at this shop. Not because we didn't

think the engine would meet our claims, but because this particular dyno operates

on a different principle than the popular Dynojet 248. When we talked to Tony,

the owner of The Racers Group, the first thing he told us was that their dyno

is a 'load bearing dyno', and unlike 'inertia' dynos this type of chassis dyno

offers more capabilities for tuning, at the expense of slightly less rear wheel

numbers.Well this immediately raised a flag. Sure tuning capabilities are nice,

but we want numbers. Just how much less were we going to see? On the order of

are 10% less than what you'd see on an inertia dyno. We had quite a bit of experience

with Dynojets, and frankly, the Dynojet is sort of an industry standard. But since

we didn't have much of a choice, we decided to see what the Bosch/Dytech dyno

would give us. The guys at Racers Group also reminded us that any dyno is simply

a tuning tool, and what is important is how much you've gained at the end of the

session. If

you've been following the progress of our 302 engine buildup and Project 11.99,

then know that we've been promising dyno numbers for the past couple months. We'd

been furiously trying to arrange some dyno time with a shop we has used in the

past. Unfortunately we never got a hold of them, so we ended up having to locate

another dyno. Well two days before this issue we finally found a shop at Sears

Point Raceway that had a chassis dyno. However let us tell you that we had some

apprehensions about getting the car tested at this shop. Not because we didn't

think the engine would meet our claims, but because this particular dyno operates

on a different principle than the popular Dynojet 248. When we talked to Tony,

the owner of The Racers Group, the first thing he told us was that their dyno

is a 'load bearing dyno', and unlike 'inertia' dynos this type of chassis dyno

offers more capabilities for tuning, at the expense of slightly less rear wheel

numbers.Well this immediately raised a flag. Sure tuning capabilities are nice,

but we want numbers. Just how much less were we going to see? On the order of

are 10% less than what you'd see on an inertia dyno. We had quite a bit of experience

with Dynojets, and frankly, the Dynojet is sort of an industry standard. But since

we didn't have much of a choice, we decided to see what the Bosch/Dytech dyno

would give us. The guys at Racers Group also reminded us that any dyno is simply

a tuning tool, and what is important is how much you've gained at the end of the

session.

We

loaded the car onto the rollers, strapped it down, and let Tony go to work. Tony,

the South African native, builds and tunes Porsche race cars for a living. Having

squeezed out 250 rearwheel horsepower out of 3.6L Porsche engines, naturally aspirated,

we had no doubts in his ability to tune our simple V8. We

loaded the car onto the rollers, strapped it down, and let Tony go to work. Tony,

the South African native, builds and tunes Porsche race cars for a living. Having

squeezed out 250 rearwheel horsepower out of 3.6L Porsche engines, naturally aspirated,

we had no doubts in his ability to tune our simple V8.

If

you've ever had your car on a dyno, you probably ran it in third or fourth gear

from idle to redline. Then the computer plots out a horsepower and torque curve.

The Dytech is a little different. It has the capability to sustain a load on the

engine so you can hold the rpms at a specific point. It is similar to being on

a treadmill that increases intensity as you try to run faster. It is truly a strange

feeling to have you foot to the floor, the engine screaming, and the tach needle

stuck at 5000 rpm. What this allows is for dead-on precise measurements at a fixed

point every time. If

you've ever had your car on a dyno, you probably ran it in third or fourth gear

from idle to redline. Then the computer plots out a horsepower and torque curve.

The Dytech is a little different. It has the capability to sustain a load on the

engine so you can hold the rpms at a specific point. It is similar to being on

a treadmill that increases intensity as you try to run faster. It is truly a strange

feeling to have you foot to the floor, the engine screaming, and the tach needle

stuck at 5000 rpm. What this allows is for dead-on precise measurements at a fixed

point every time.

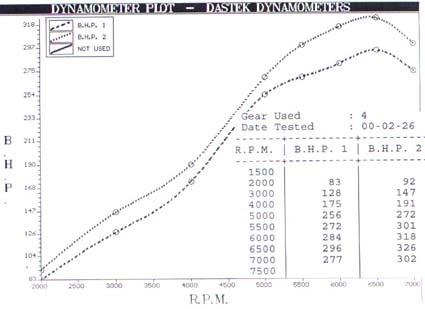

So

with the car loaded and ready to go, Tony made a base line run. The initial run

made us shake our heads in disbelief. The machine spit out a peak horsepower of

296 at 6500. However Tony detected wheelspin, and also felt the car was running

lean. He also hooked up a wide-band 02 sensor in the header collector, lowered

the tire pressure, and made another pull. This time he immediately noticed the

air-fuel ratio was on the lean side, (around 17.0:1) so we worked on isolating

if it was the primaries or secondaries that were lean. Holding the pedal so that

only the primary throttle blade were open, we could see the AF meter read lean.

We stopped the pull, and jetted the primary side up from 75 to 79, and repeated

the test. Oddly enough the meter showed no change in the A/F ratio, leading Tony

to believe it was not reading correctly. Upon further investigation he determined

that the A/F meter was not exclusively reading exhaust gases, but was being contaminated

with ambient air. The reason for this is pretty simple. An O2 sensor is made to

work upstream in an exhaust system, where there is only exhaust flow before and

after the sensor, however since we were running open headers, the meter was picking

up outside air at the collector. Tony

then decided to go with a carbon monoxide (CO) meter, similar to the ones used

in tailpipe smog checks, which can be inserted higher up in to the header tube.

This time the numbers showed just the opposite, that in fact we were too rich

(6.8% CO) and were passing raw fuel through the exhaust. We removed the ram air

box, to let the carb breath on its own. We tore in to the primary metering block

a few more times, bringing the jetting down to 70. This got the CO to 1.5%, which

is great for passing emissions, but a bit to lean for making power. We bumped

the primary jets to 73 and obtained a 2.5% reading. This would equate to an air

fuel ratio of around 15:1, which is perfect for part throttle driving.

Next

we focussed our attention on the secondaries, under wide open throttle conditions.

We had pulled into the shop with 76 jets in the secondaries, which turned out

to be lean. We ended up jetting up to 80's to yield a a wide-open throttle AF

ratio of 14:1.  With

the jetting dialed-in, Tony suggested we check the timing. In past dyno sessions,

we'd proceed by adjusting the timing up or down a couple degrees, followed by

a pull. Then we'd analyze the data to see if we gained or lost power. Tony said

he had a better method; with the dyno loading the engine at 5000 rpm, we got in

and put the pedal to the floor. With the engine stuck at 5000 rpm, Tony rotated

the distributor until the LED horsepower display showed maximum power at 5000

rpm. We witnessed the power go from as low as 270 to as high as 300. That is a

30 horsepower difference by simply getting the timing adjusted properly. When

then checked the setting with a timing light, and found total to be at 41 degrees,

we previously had it set at 38. With

the jetting dialed-in, Tony suggested we check the timing. In past dyno sessions,

we'd proceed by adjusting the timing up or down a couple degrees, followed by

a pull. Then we'd analyze the data to see if we gained or lost power. Tony said

he had a better method; with the dyno loading the engine at 5000 rpm, we got in

and put the pedal to the floor. With the engine stuck at 5000 rpm, Tony rotated

the distributor until the LED horsepower display showed maximum power at 5000

rpm. We witnessed the power go from as low as 270 to as high as 300. That is a

30 horsepower difference by simply getting the timing adjusted properly. When

then checked the setting with a timing light, and found total to be at 41 degrees,

we previously had it set at 38.

With all the tuning out of the way we

geared up for a full run to see what we'd gained. The pull was carried out to

7000 rpm to see where power drops off. This time the numbers were more palatable,

as peak was now 326 horsepower at 6500 rpm. We had gained 20-30 horsepower across

the board from our first run, not bad for a two hour tuning session. Torque, which

is calculated using the horsepower data, showed a peak of 287 at 5500 rpm.

click

here for torque curve

Analyzing the Results

The Bosch manual

for this dyno indicates that power loss for a manual transmission car, in fourth

gear, is between 25% to 30% from flywheel to rearwheel. This seems high to us

(inertia dynamometers like the Dynojet claim around 15-18% loss through the drivetrain

for a manual car), but Tony ensured us that his experience with testing on both

engine and chassis dynos, proves this to be accurate. Keep in mind the Bosch/Dytech

shows 10% less at the rearwheels. What we'd like to do in the near future is make

a couple pulls on a Dynojet, and compare the numbers with what we got here.

Did

we meet our goal?

Definately. If we take the conservative approach and

add 20% to the 326 HP obtained on this dyno, that puts flywheel horsepower at

391. Keep in mind this is without the effects of ram air, which we cannot measure

in a dyno room. We figure the ram air is worth at least 10 horsepower at

the rear wheels, in reality it's near double that. That would put us at over 400

horsepower.

We'd like to thank Tony and the guys at The Racers Group

for taking the time to tune our car and answer our questions. We had only planned

on spending an hour and making a couple baseline pulls, but we left with 30 more

horsepower, and a greater understanding of using the dyno as a tuning tool. We

thought the car was running great before we came in, so it will be very exciting

to see what we turn the next time out at the track! F/M

|